Service Hotline

+1 4152729688

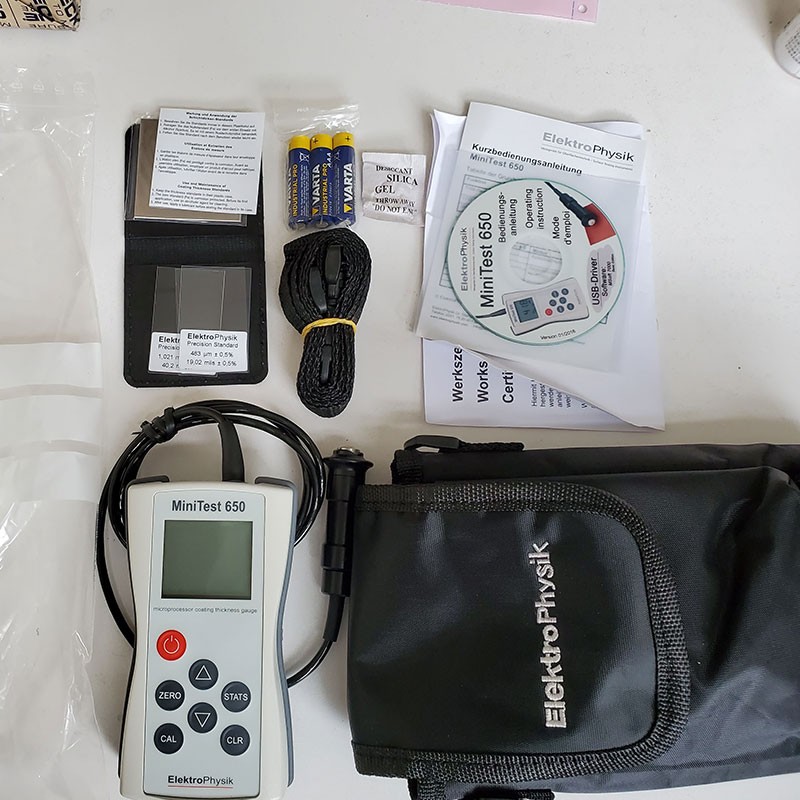

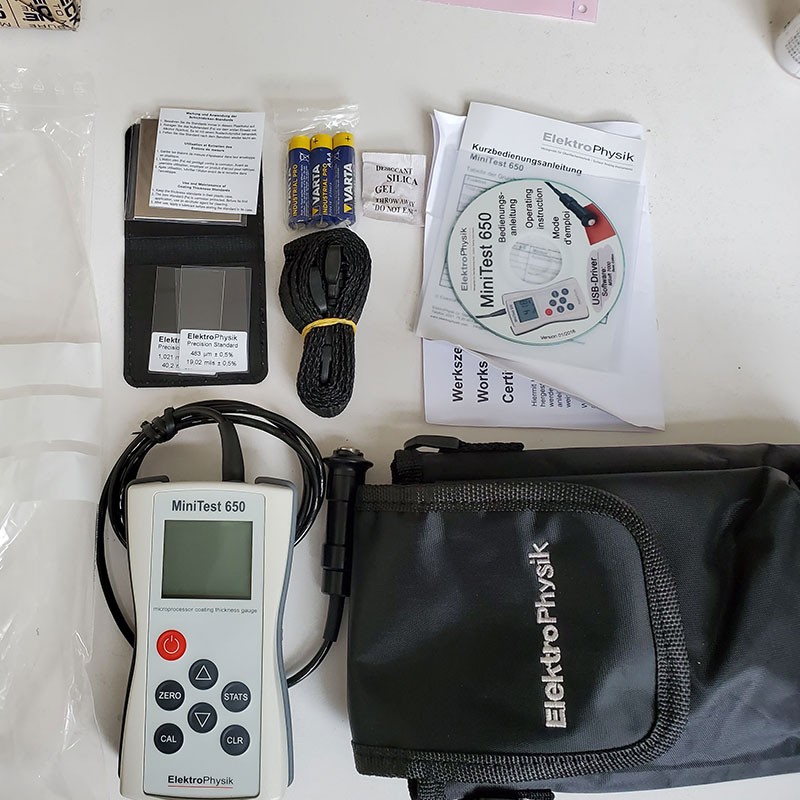

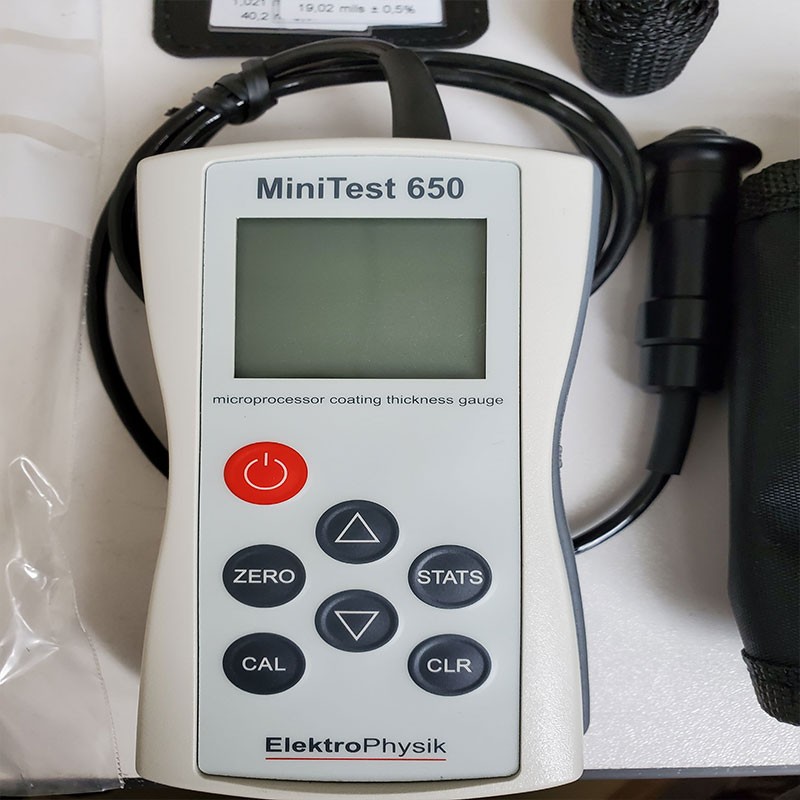

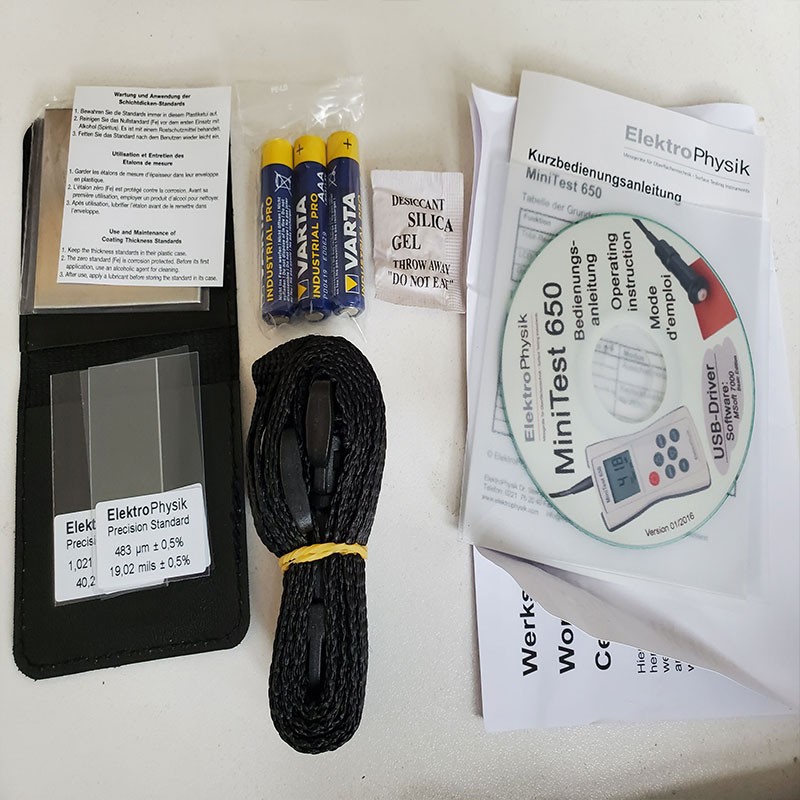

Product Description:

Technical specifications of ElektroPhysik coating thickness gauge:

Model name/number: Micro measurement 6G

Model/Name: Mikrotest 6G, Mikrotest 6G

Resolution: 1 micron

Minimum measurement area: 20mm

Minimum sample thickness: 0.05 mm

Display type: Analog

Measurement range: 0-100 microns

Color: Yellow

Purpose/Application: Used to inspect coatings on steel

Brand: ElektroPhysik from Germany

Battery life: No battery required

Accuracy:+/-1 micron

Display resolution: 1 micron

Minimum count: 1 micron

Packaging type: plastic box

Weight: 1 KG

Functional characteristics of ElektroPhysik coating thickness gauge:

1. Prevent corrosion and wear

The surface coating can be paint, plastic, or metal, such as zinc plating, chromium plating, or nickel plating. To ensure that the coating/measurement range can fully protect the underlying material from corrosion or wear, a certain thickness is required, depending on the product being coated. This is where the measuring instrument used for testing layer thickness comes into play, using a surface measurement technique that reliably measures coating thickness.

2. Non destructive coating thickness gauge

Coating thickness measurement can be roughly divided into destructive and non-destructive measurement methods. Non destructive methods are clearly preferred as they can be used for random sampling and large-scale quality control. However, in the past, it was almost impossible to measure coating thickness without damaging the protective coating. That's why ElektroPhysik can proudly say that we make it work. Due to years of progress, growth, and continuous improvement, we are able to provide customers with instruments that combine traditional and mature functions with modern technology and design.

3. Method of coating thickness gauge

There are several measurement methods and coating thickness gauges available to protect coatings. These include magnetic induction methods for measuring non magnetic coatings (paint, varnish, etc.) on magnetic substrates, eddy current methods for measuring non magnetic metal layers on non ferritic metals, and ultrasonic measurements of non-metallic coatings on non-metallic substrates.

4. Coating thickness gauge that meets various needs

We can use various devices for precise coating thickness measurement based on specific application fields, from small universal coating thickness gauges with radio probes, Bluetooth, and USB connections to high-end thickness gauges with a large number of external sensors and graphic displays, as well as precision coating thickness gauges using ultrasonic pulse method and classic mechanical measurement equipment MikroTest.