Service Hotline

+1 4152729688

1. High robustness

2. High resistance to water vapor and particles/dust.

3. Expand according to customer requirements.

4. Very high pumping speed.

5. Do not pollute the pumped medium.

6. Friction free rotation - eliminates rotor wear.

7. Due to internal compression, the efficiency is very high.

8. The operating costs and maintenance requirements are relatively low.

9. Frequency converter operation - easy to optimize for process requirements - brings high energy efficiency.

10. Gas ballast required for pumping light gas.

If there is no gas ballast, the ultimate pressure and pumping speed of light gases (helium and hydrogen) will decrease.

12. Unable to scale down to 50 meters ³/ Small pumping speed below h; Below approximately. Using 100 meters ³/ H multi-stage Roots pump or vortex pump.

Spiral pump model:

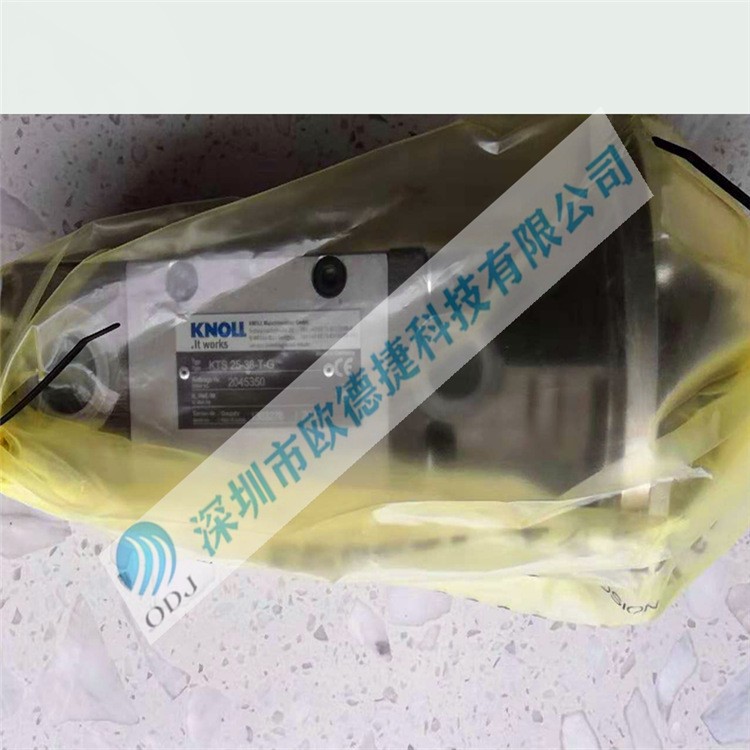

Knoll screw pump KTS 32-64-T

KNOLL screw pump KTS 25-50-T-A-G-KB-H-B

Knoll screw pump KTS 20-48-T-KB

Knoll screw pump KTS 25-50-T-KB

Knoll screw pump KTS 25-38-T

Knoll screw pump KTS 32-64-T-G-KB

Knoll screw pump KTS 25-50-T-G

Knoll screw pump KTS 40-96-T-G

Knoll screw pump KTS 25-60-T

Knoll screw pump KTS 40-60-T

Knoll screw pump KTS 25-50-T-A-G-KB

Knoll screw pump KTS 32-48-T

Knoll screw pump KTS 25-60-T-G

Knoll screw pump KTS 25-60-T-G-KB

Knoll screw pump KTS 20-40-T-KB

Knoll screw pump KTS 25-38-T-G

Knoll screw pump KTS 25-50-T

The Knoll screw pump can reach an ultimate pressure of approximately 1e-3 mbar. The working pressure range is 10 3 to 10-2 mbar. Provide pumping speeds of approximately 60-1200 meters ³/ Various sizes of h. By placing a Roots blower at the top, the suction speed within the vacuum range of<10-50 mbar can be increased. These combinations are typically located in one pump casing, up to a maximum of 9000 meters ³/ H.

Knoll screw pumps have become the standard solution for almost all industrial vacuum processes. Vacuum furnaces used for brazing or sintering, metallurgical systems, and even steel degassing equipment have the advantages of dust prevention and long service intervals. In food processing, food drying, food packaging, and even freeze-drying machines tend to use oil-free KNOLL screw pumps to avoid pump oil being contaminated by water or debris during the process. Large scale coating machines such as architectural glass coating machines use Knoll screw pumps as the crude extraction pumps for high vacuum pumps. Knoll screw pump is also an ideal choice for large-scale low-temperature pump regeneration.