Service Hotline

+1 4152729688

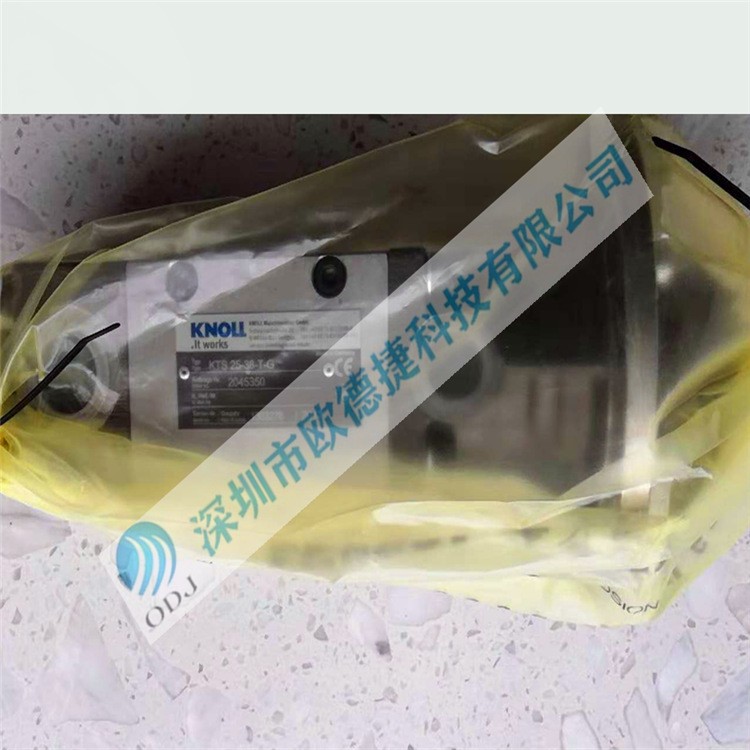

1. Optional wear-resistant SIC piston liner, with minimal wear and long service life at throttle clearance.

2. The precision design of the screw and special steel are used for the spindle.

3. The barrel casing is precision machined by SIC, making it almost wear free.

4. Compensate through the wear-resistant axial thrust of hydraulic bearings and continuously lubricate the spindle in the liquid lubrication film.

5. All pumps are available in submersible versions, which can be installed vertically or foot mounted for horizontal dry installation.

Equipment advantages and application types

Low wear of ceramic barrel shell - T/- F

Mechanical seal for dry installation - G

Ceramic piston liner housing in throttle point 2 is wear-resistant 5-KB

Axial thrust compensation, running the spindle to guide better pressure relief vibration performance in ceramic bushing 2- A

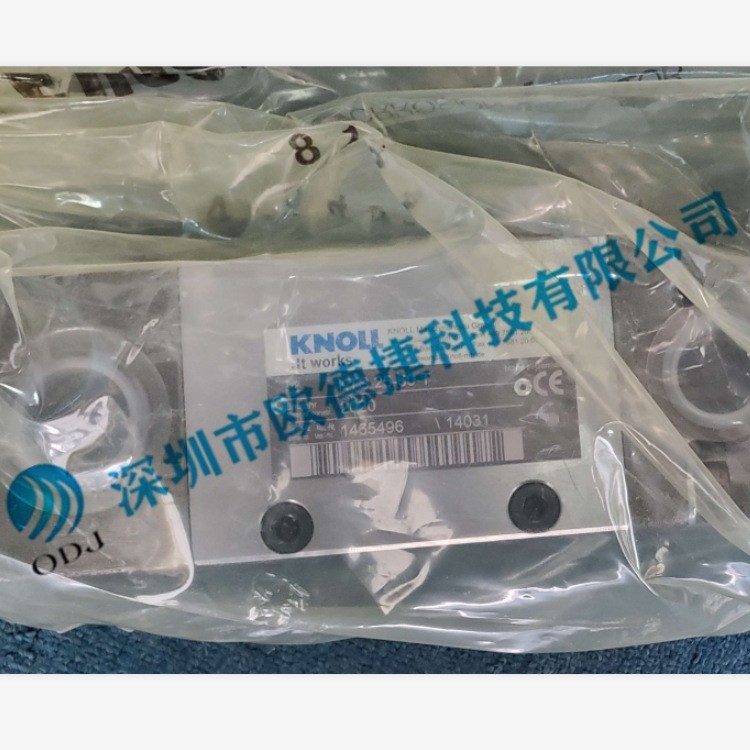

Characteristics of Knoll screw pump:

1. Main bearing external

2. High wear resistance

3. Long service life

4. High temperature resistance

5. Low noise

6. Mild pumping of liquid

7. Self priming positive displacement pump for lubrication and reducing abrasive media

8. Oil suction sleeve

9. Running sleeve with drive spindle and two rotating spindles, third pressure housing with throttling point, sealed shaft channel and external main bearings

10. The barrel shell is composed of two ceramic shells embedded in steel, and the spindle pack is made of specially treated tool steel