Service Hotline

+1 4152729688

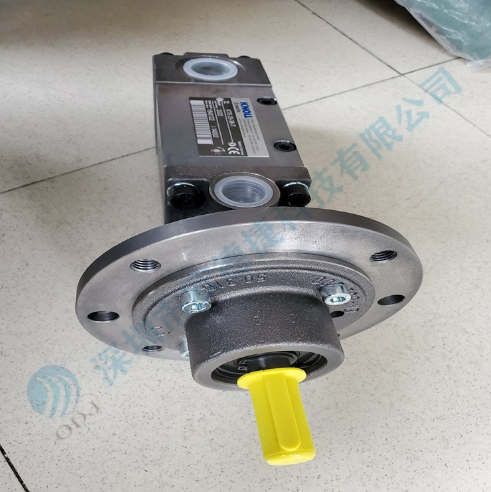

Basic parameters of Knoll screw pump:

Manufacturer: KNOLL

Model: KTS 32-64-T-G-KB

Condition: Original brand new

Weight: 32KG

Maximum: 79.4 liters/minute

Maximum: 150 bar

Power demand: maximum

Shaft: Ø 24 mm

Flange: Ø 212 mm

Aspect: 450 x 212 x 212 mm

Code: Pump 376

Important components of Knoll screw pumps:

1、 Screwdriver (outer rotor)

A screwdriver is one of the rotating components of a screw pump. It helps to pump fluid at a constant volume level at any position.

The main function of a screwdriver is to drive the driven screw through the timing gear.

2. The screwdriver is made of high-strength steel.

2、 Driven screw (inner rotor)

The driven screw transmits motion through the timing gear and rotates along its axis.

1. Unlike a screwdriver with a fixed gap area, it rotates in the opposite direction.

2. Since the gap area between the driver and driven screw remains unchanged and they rotate in opposite directions, the fluid moves along the rotation angle to provide non pulsating output.

It is also made of high-strength steel.

3、 Timing gear

The drive and driven screws have a very fine gap area during operation, so there is always a chance of contact. If this is not considered, it may lead to some unexpected situations.

Therefore, the timing gear is installed on the screw pump to verify such events.

2. The timing gear fundamentally drives the driven gear in such a way that there is no chance of metal to metal contact between the male and female rotor components.

4、 Suction and discharge ports

To prevent the pump from drying out, the suction and discharge ports provide starting liquid medium to the screw pump.

5、 Bearings

There are usually two types of bearings. The bearing that bears heavy loads and axial and radial forces during pumping operation is called the upper bearing, while the bearing that bears the minimum load has the key task of maintaining the alignment of pump components. It is called the lower bearing.6、 Transmission shaft

It is a component of the pump that is connected to its drive motor using a set of appropriate adaptive couplings.

1. The drive shaft is an integral part of the pump.

On most pumps, the drive shaft is made of low-carbon steel and the drive screw is connected to the motor for operation.