Service Hotline

+1 4152729688

2023-09-21 11:49:40

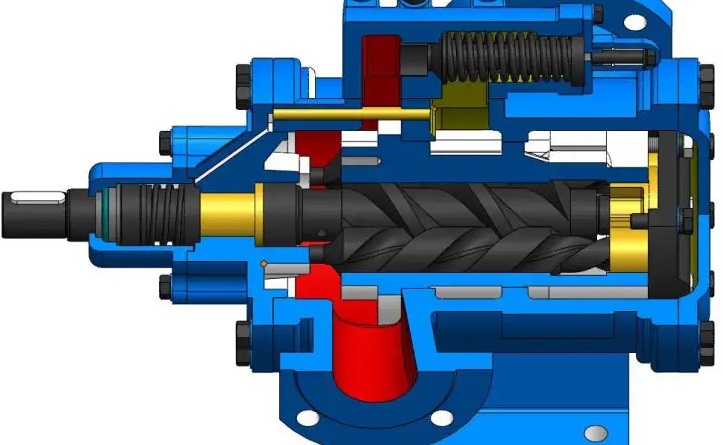

Knoll screw pumpEven if it can withstand extreme operating conditions; It does require maintenance and good housekeeping to extend its service life. Never deliberately make the screw pump idle; Because any idling for more than a minute or two will damage the pump components. Care must be taken to avoid extreme pressure build-up due to closure of the output valve.

This is so because the circulation valve is in this state (100% recirculation); Can only withstand the increasing pressure for four or five minutes. Make sure all connections are lined up correctly. I mean; Make sure the input and output pipes are connected as planned. Make sure there are no leaks in the pump or connected lines.

Proper inspection and maintenance must be carried out regularly; The time between maintenance schedules should not exceed three years. Suction and delivery pressures must be monitored regularly, and pump filters need to be cleaned quarterly. A dirty or blocked suction filter will result in reduced suction pressure.

Similarly increased noise and vibration followed by reduced emission pressure; Is a clear indication of wear inside the pump. If too much air is drawn into the system resulting in no emissions or reduced emissions; Increase the pump speed while sealing its inlet to correct the situation. Now, if you are struggling to get your screw pump self-starting, the remedy is to reverse the direction of operation; As a screw pump, it will not start due to incorrect rotation direction in most cases.

The above content is the method of late maintenance of knoll screw pump, hoping to help you use screw pump. Shenzhen Oudejie technology professional sales of original imported knoll screw pump, and committed to sales of screw pump products are new original imports, while providing our customers with quotation, selection, product information and other services.