Service Hotline

+1 4152729688

2023-09-21 09:13:50

Swivel jointFunctions by connecting a fixed input (supply) to a rotating part, allowing the mobile connection to be retained and allowing the medium (liquid, solid and gas) to flow.

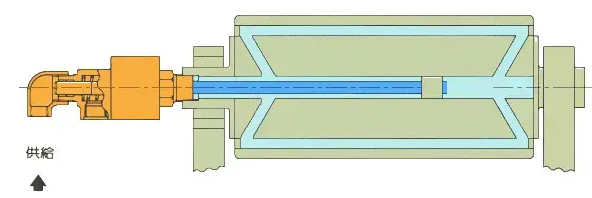

D aul Flow (inner tube rotation) The working principle of the rotary joint

The inner tube is closely connected with the drum to prevent the backflow of fluid and affect the heating efficiency of the drum.

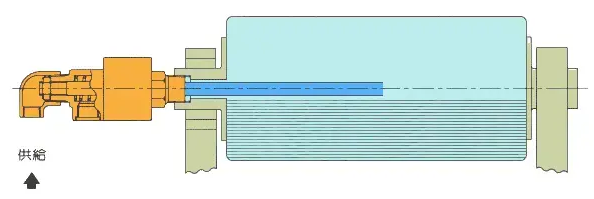

D aul Flow (inner tube rotation) The working principle of the rotary joint

The siphon is installed in the roller to remove condensation. This type is mainly used for steam

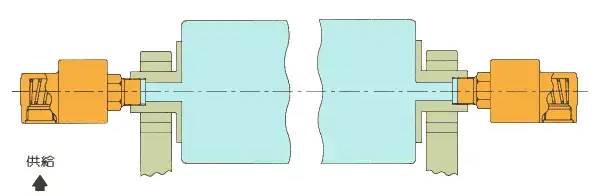

D aul Flow(inner tube rotation) The working principle of the rotary joint

The swivel joint is installed at one end of the drum to allow fluid in and out.

Single Flow Working principle of rotary joint

The rotary joint is the flow device at both ends of the drum. Fluid enters at one end and exits at the other. No inner tube needed.

Rotary joint selection procedure.

1. First determine the type of rotary joint according to its structure: the same side of the device, if the structure of the device determines that the input and output media are realized on the same side of the device, then the composite rotary joint must be selected. If it is on both sides of the device, a single channel swivel must be selected.

2. If the device needs to transmit multiple media or output media to multiple locations, you should consider choosing a multi-channel rotary joint.

3. Select the size of the rotary joint according to the medium flow rate.

4. According to the pressure of the medium and the speed of the equipment to choose the corresponding performance of the rotary joint.

5. According to the connection structure of the device and the rotary joint, determine the embedded, flanged or threaded connection and the rotating or fixed connection of the inner pipe. Also keep in mind that if you choose a threaded swivel, you must determine the direction of rotation of the device.

6. If the user is not convenient to choose the type of rotary joint, the following parameters can be provided, and our company is responsible for providing you with a choice.

7. Connection structure and related dimensions of equipment and rotary joint.

8. Rotate the speed and direction of the joint.

9. Media, temperature and pressure.

10. Connection size of rotary joints and metal hoses.