Service Hotline

+1 4152729688

2023-09-21 09:34:39

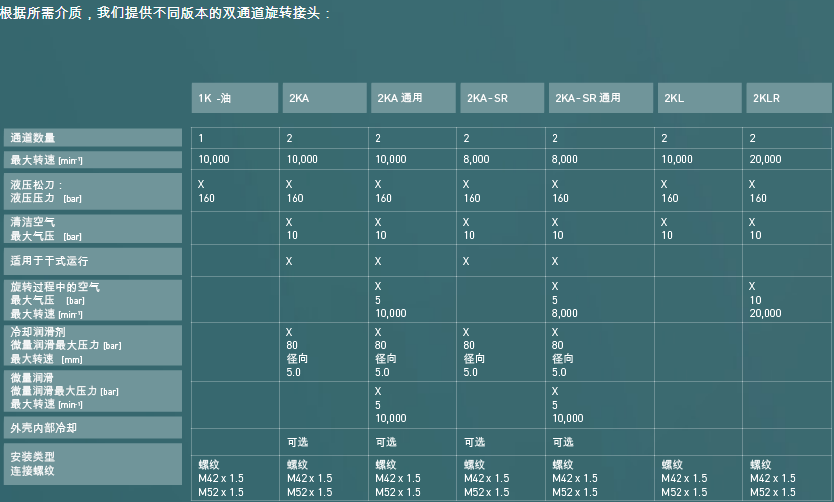

Rotating jointIs a type of machine that transfers liquid or liquid dielectric data from a fastening component to a rotating component. OTT-JAKOB's rotating contacts enable data transmission through a variety of dielectrics through the subject. My product range includes twin engines with multiple underpass rotating contacts for pumps, air, heating adhesives, high concentration sterilization, subject internal heating and high temperature grinding.

1. Dual engine oil

The twin engine oil rotation contacts can be directly screwed on the subject and provide an economical solution for the roller control system to loosen the cutter.

2. DDR3

Through my DDR3 rotating contact, it is possible to transport the cooling control system used as the roller control system loose knife on one underpass and another type of dielectric in the second underpass. The contacts are assembled on the theme.

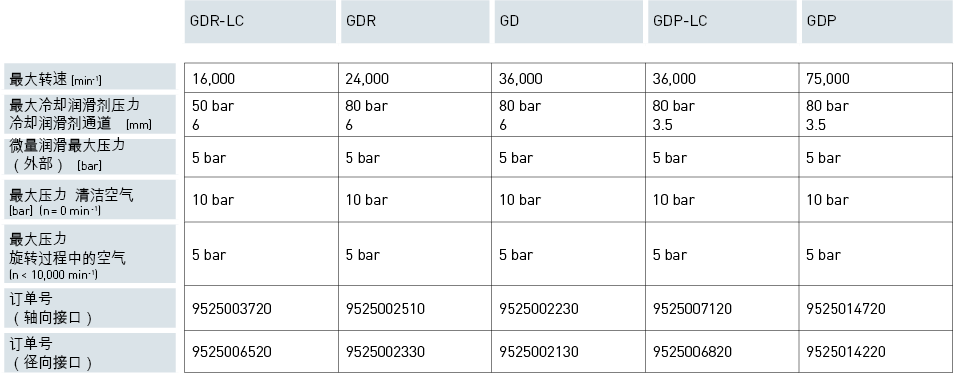

3. Dual-engine GD and dual-engine GDP

The twin-engine GD and twin-engine GDP rotational contact is characterized by a permanently semi-enclosed closed surface (GD). In addition to being used as most commonly used dielectrics, the exclusive seal enables unconstrained post-treatment grinding while minimizing leakage.

The built-in quality blend pump offers low impedance and a short base oil life for long performance at low speeds. Through the dungeon-type sealing, the pump can effectively avoid environmental pollution, and continue to improve the life of the pump. Heating adhesive USB can be rotated 360°, easy to install. Most GD rotary contacts are available in axial and axial USB versions. Predictable protection cycles guarantee the worst ease of use.

The GD rotating contact is installed on the OTT-JAKOB cutter. The addition diameter of about 48 mm(GDP 32 mm) as expressed by OTT-JAKOB remains the applicable international standard for the industry.

Dominated by international standard categories, the OTT-JAKOB product range also includes special rotating contacts designed for the rigorous requirements of milling machines and welding grinding, such as:

Used for a low number of users

Used for lower output power

Used when space is limited

Built-in leakage sensor