Service Hotline

+1 4152729688

2023-09-21 09:57:40

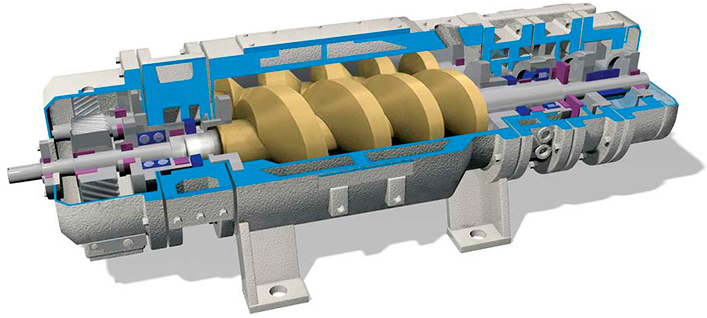

Screw pump is a rotary pump, it is a form of positive displacement pump, it each turn to transport a known amount of fluid. Screw pump consists of various components, such as: housing, screw (depending on the type of screw pump; It can contain 1 screw, up to 5 screws), bearings, seals, motor adapters and drive shafts. Screw pump structure is very simple.

A screw pump works by the form of a screw similar to a thread, so by rotating it, fluid moves along the thread from the suction side of the pump to the discharge side. The clearance within the pump is very close and volumetric efficiency is high, especially for viscous fluids, as this reduces the amount of fluid slippage from the high pressure to the low pressure side. As with any positive displacement pump, the pump itself does not generate pressure, it only moves the fluid, but it is the actual system that generates back pressure due to friction losses.

Knoll screw pumps are primarily used for fluids with higher viscosity, and moving these fluids with a screw pump results in an energy efficient and relatively compact machine compared to other pump types (i.e., centrifugal pumps). For screw pumps with more than 2 screws, they are usually used only for lubricating fluids, simply because the screws are not meshed together and rely on fluid to lubricate the screws. For twin screw pumps, the screw is geared to prevent the screw from touching each other, so the flow rate for non-lubricating fluids, chemicals and food can be higher than higher screw pump types, that is, more than 2 screws. The main applications of screw pumps are oil-based fluids, tar bitumen, adhesives (industrial type), chemicals and dairy products.

The type of screw pump is also divided into many kinds, depending on the number of screws - 1 screw to 5 screw changes, of which 2 screw pumps (also known as double screw pumps) are the most common, where the gears must be together to prevent contact. In terms of being able to handle entrainment of air or gas (including gas clumps), the double screw pump can be quite tolerant, and in this case you can not use a 3 screw pump, because the screw is likely to touch together. When more than 1 screw is involved, it is usually called a multi-screw pump. The structure is relatively simple and enables higher flow rates. They can also be used in self-priming applications with the correct suction pipe configuration.

The above is the composition of the screw pump and its application scenario analysis, need to understand the original imported German knoll screw pump price can directly consult Shenzhen Oudejie Technology Co., LTD.