Service Hotline

+1 4152729688

2023-09-21 10:00:17

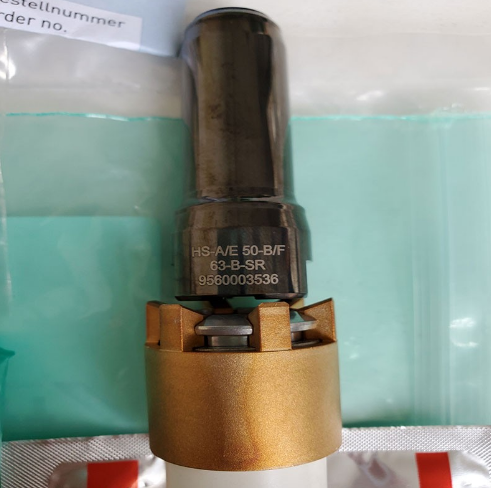

OTT-JAKOB spindle gripper is a very important tool in mechanical equipment, which can clamp, seal, and fix processed workpieces. Spindle grippers are widely used in CNC machining machines, mechanical milling machines, and other machining machinery. The principle is to control the cutting tools such as milling cutters by pre setting the clamping force, and then clamp the workpiece to maintain its uniformity and stability, thereby ensuring processing quality and consistency.

When using the spindle gripper, it is necessary to place the gripper next to the workpiece and clamp it by pulling the handle. The handle controls the movement of the gripper, thereby tightly fixing the workpiece to prevent displacement during the machining process. After clamping, the machine starts processing, while the spindle gripper maintains and controls the fixation and position of the workpiece throughout the entire processing process. After the machining is completed, the spindle pawl is released from clamping by pulling the handle again, in order to complete the unloading of the processed workpiece and the processing of the next group of workpieces.

The principles of OTT spindle grippers can be further divided into two categories: mechanical clamping and pneumatic clamping. From the name of the latter, it can be expected that pneumatic clamping mainly uses compressed air pressure to clamp the workpiece, while mechanical clamping mainly uses mechanical parts such as handles, bolts, screws, etc. to clamp the workpiece.

For mechanical clamping, three claw and four claw clamping are more common. Three jaw clamping uses three feeding gears to move the clamping jaws to grip the workpiece. Four jaw clamping uses four clamps to stabilize the workpiece. Regardless of the type of clamping used, by repeatedly adjusting the clamping force to achieve the desired clamping degree, it is ensured that the processed workpiece will not shift.

On the other hand, pneumatic clamping mainly includes high-pressure and low-pressure gas type clamping. High pressure gas type clamping is based on the principle of template fixtures, using high-pressure gas, such as a pneumatic oil pressure system, to pressurize the jaws. Low pressure gas type clamping uses gas quality and slow pressure devices to achieve clamping. Both methods use gas pressure, but the different implementations on components such as fixtures, cylinders, and hydraulic pumps are based on their specific applications.

In short, its principle is to control the movement of the machining tool and the position of the workpiece through pre-set clamping force and clamping method, in order to maintain the firmness and stability of the workpiece during the machining process, thereby ensuring excellent machining results. This application can be extended to many industries, including automotive, electronics, manufacturing, aerospace, and other fields, and is constantly innovating and improving to adapt to the development of new technologies such as robotics and automatic control.

The above content introduces the working principle of OTT-JAKOB spindle gripper. In addition, Shenzhen Oudejie Technology specializes in selling new original imported OTT-JAKOB spindle pullers, and promises to sell all products with new original imports. At the same time, we provide customers with quotation, selection, product information and other services. For more product and technical information needs, please go to the ODJ-Tech Global LLC official website to search for contact information and further consult and understand.