Service Hotline

+1 4152729688

2023-09-22 16:27:25

Cavitation, which often affects equipment, especially hydraulic machinery such as pumps, occurs when the pressure in the loop is equal to or lower than the steam pressure of the fluid being transported.

What is involved in cavitation?

Cavitation is the instantaneous evaporation of a fluid, mainly in areas of very low absolute pressure, followed by rapid recondensation.

The bubbles created when the bubbles burst create high-pressure miniature objects, which can lead to subsequent corrosion of the affected mechanical parts.

The most affected areas are the contact areas between the fluid and solid surfaces of the pump (impeller and housing), or the areas where the fluid is in contact with small suspended particles inside the fluid, which themselves develop noticeable cracks and vibrations.

Damage caused by cavitation

In practice, cavitation leads to a number of damaging effects:

• Corrosion of mechanical parts in direct contact with fluids

• Eddy currents due to surface irregularity of the surface, resulting in decreased performance.

• Excessive vibration caused by weight imbalance and excessive impeller speed

• The service life of the pump/circuit is shortened due to aerodynamic wear of mechanical components (e.g. bearings, seals, etc.)

• Damage

How to prevent pump cavitation

This phenomenon is caused by the following circumstances:

• High head

• Large load loss in the pump input section

• Height difference between pump and fluid surface

• High liquid vapor level (increases with temperature)

• Mathematical instruments can be used to reduce the risk of cavitation.

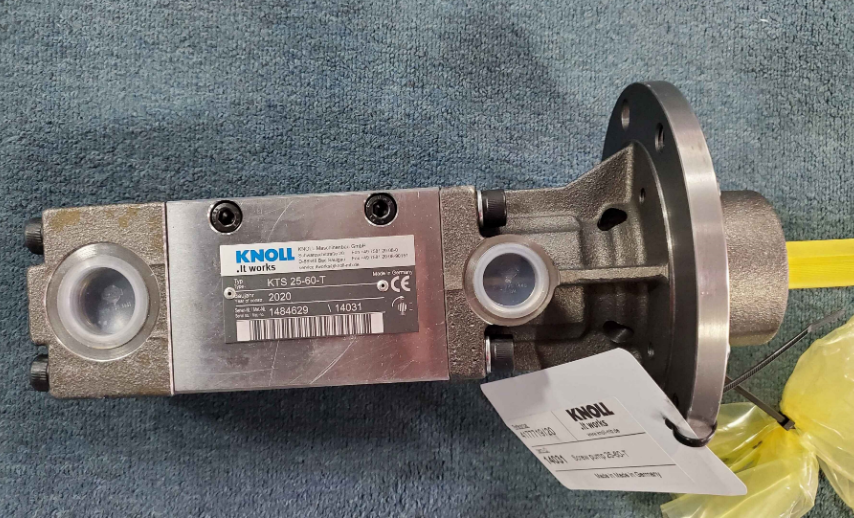

What is pump cavitation introduced above,KNOLLKono centrifugal pumpThe cavitation is what the problem is. In addition, Shenzhen Oudejie Technology specializes in selling new imported KNOLL centrifugal pump pumps, and promises to sell products are new imported original, while providing our customers with quotation, selection, product information and other services.