Service Hotline

+1 4152729688

2023-09-22 16:10:12

The obvious reason for using leak detection equipment is for environmental protection, as many materials transported and stored through pipelines can pollute the environment.

Leak detection is another step to improve your organization's operations. Proper management and control ensures that equipment functions flawlessly and protects assets, a combination that can lead to financial success.

Prevent losses with leak detection

While the primary focus of leak detection is environmental protection, another factor is the costs associated with leaks and loss of assets. Each leak allows profitable material to escape and cannot be recycled. This greatly affects the company's bottom line. With an efficient and reliable leak detection system, any type of product loss can be greatly reduced or completely eliminated.

Pinpoint leaks

Leak detection systems pinpoint the location of leaks so they can respond immediately to control and eliminate them.

Non-invasive leak detection

Leak detection equipment does not affect the operation of the facility. They are close to key areas that can provide the greatest amount of data. They are installed without disrupting or stopping operations, but their primary function is to protect resources and personnel.

The labor-saving benefits of leak detection

In the past, the only leaks that drew immediate attention were visible or small ones that caused disaster. The process of finding vulnerabilities requires digging and effort. Modern leak detection devices can identify, locate, and map a leak before it becomes visible, and have the added advantage of avoiding the need for digging and searching. As a result, leaks were found and repaired with minimal damage.

Leak detection is an important part of the Environmental Protection Agency's (EPA) concern because leaks are a source of volatile organic compounds (VOCs) and volatile Hazardous air pollutants (VHAP). To help manufacturers and users of leak detection equipment, EPA has issued leak detection equipment repair and replacement guidelines.

The EPA guidelines are intended for use by regulated industries, such as refiners and chemical producers. The material in this guide covers a variety of issues related to leak detection and repair (LDAR) procedures. There are provisions for different practices that can be used to improve the effectiveness of LDAR procedures.

EPA research shows that 70,000 tons of VOCs and 9,000 tons of HAPs are released into the environment each year due to equipment leaks. The recorded leaks include all materials and containers, including storage containers, wastewater treatment facilities, gas, oil and liquid transfer sites, and processing vents.

Vocs are part of the formation of ground-level ozone, which is a major part of smog production. Inhaling VOCs can cause respiratory problems in children, asthmatics and healthy adults.

To control the spread of harmful emissions, EPA recommends implementing leak detection and repair programs and replacing equipment where leaks have been detected with non-leak components. Leak regulations provide options for controlling leaks and developing leak detection practices.

Common leak sources that require leak detection equipment include:

• Pump - Leak occurs in seal

• Valves - Leaks occur in the stem or gland area

• Connector - leakage due to washer failure

• Sampling connector - The leak occurs at the outlet of the line

• Compressor - seal leak

• Pressure relief device - The leak is caused by improper valve installation and disc rupture

Open line - Leaks occur where the line is open to the atmosphere

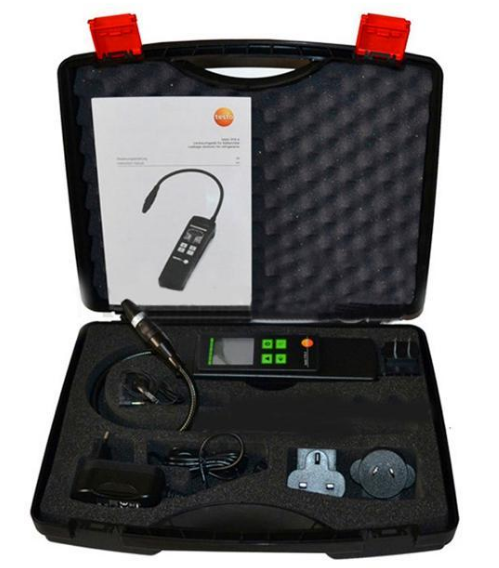

The above describes Germanytestorefrigerant leak detectorWhat are the advantages? The use of refrigerant leak detector regulations. In addition, Shenzhen Oudejie Technology specializes in selling new imported testo refrigerant leak detector, and promises to sell products are new imported, while providing our customers with quotation, selection, product information and other services.