Service Hotline

+1 4152729688

2023-09-22 11:32:50

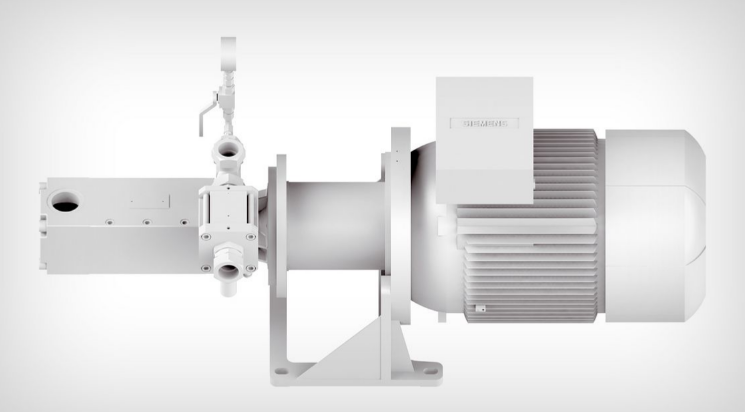

Centrifugal pumpIt's a machine that converts kinetic energy into a fluid head. External power from a diesel generator or electric motor then turns the pump impeller. Under the action of centrifugal force, the fluid enters the impeller, reaches its tip and leaves the volute. There are many types of centrifugal pumps, such as chemical pumps, vertical pumps, impurity pumps and so on. They can be classified according to flow type, series (single and multistage pumps), and volute type (single and double volute).

Maintaining the pump is easy; Most measures are given in the manufacturer's guide. If used and maintained properly, centrifugal pumps can last a long time and cost less. Choose a pump that is compatible with the pump that needs to be used, for example when pumping hazardous chemicals, chemical pumps are recommended.

Centrifugal pump maintenance and maintenance:

1, determine the maintenance frequency of the inspection and repair pump. A certain time frame should be set to check the pump and verify that it is still working properly or as required.

2, should regularly check and replace mechanical parts. Inspections can be quarterly, routine, or annual. The inspection includes steps such as checking the pipe for leakage, checking bearing temperature, increased vibration, unnatural and uneven noise, stuffing box, mechanical seal, discharge pressure and working current. For the annual inspection, check that all mounting points are secure, clean the filter, check that the pump flange is not leaking, replace the mechanical seal, check the coupling, change the lubricating oil and check the shaft alignment.

3. Replacing the lubricating oil of the pump is an important part of the annual inspection procedure or regular maintenance. It is essential to prevent bearing damage. When lubricating the motor, you should remember to follow the manufacturer's guidelines. Be careful not to over - or under-lubricate the system. Excessive lubrication can damage the pump more than insufficient lubrication, and to prevent this, the manufacturer's instructions must be followed. If the pump is used frequently every day, it needs to be lubricated frequently.

4, check the motor as a way of preventive maintenance is very important. Check the insulation resistance of the connections to ensure that all connections are correct and securely secured, and check the motor for signs of blocked vents or overheating.

What is the KNOLL centrifugal pump? How should the centrifugal pump be maintained? The problem. In addition, Shenzhen Oudejie Technology specializes in selling new imported KNOLL centrifugal pumps, and promises to sell products are new imported products, while providing our customers with quotation, selection, product information and other services.