Service Hotline

+1 4152729688

2023-09-21 17:30:52

From automotive manufacturing to medical technology: profiles, tubes, cladding, ring belts and more parts are made of rubber compounds. These mixtures consist of formulations optimized specifically for this purpose, although most laymen will simply define them as "rubber."

In addition to the basic formula, the machine technology of the extruder is also responsible for the shape of the rubber product and especially for the most consistent quality possible. Although the form conforms to the tool used, the quality actually depends on the "intrinsic quality" of the extruder. Therefore, engineers working for extruder manufacturers always focus on extruder technology in order to have a positive impact on quality through further development.

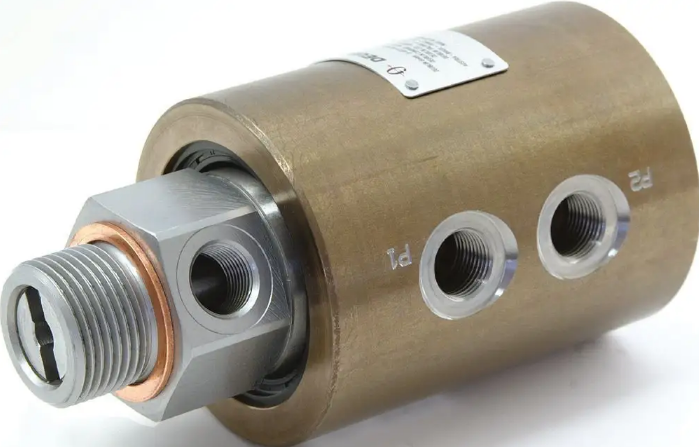

The necessary temperature adjustment of the extruder screw is performed using the DEUBLIN Dubrin swivel joint. This temperature regulation is state of the art and is a general prerequisite for maintaining technical parameters.

However, development engineers want to do more to improve the quality and repeatability of their production results and have adopted the concept of further tempering machine parts.

This is how the process of temperature regulation of the top and bottom rotors of the gear pump is implemented using additional DEUBLIN Dubrin rotary joints. Therefore, gear pumps already have advantages in terms of more equal output and constant dimensional accuracy, because feeding before the die (tool) is more efficient than simply feeding through the extruder screw. In addition, tempering the pump allows for better distribution of the rubber mixture while improving the quality of the mixture.

Of course, it is a matter of course that heat must be applied to the thermoplastic material being extruded, but there is one place in the extruder where cooler temperatures have better results: the feed roller.

Colder, more stable wires feed better and can be fed more consistently into the extruder.

By using smaller, more compact swivel joints, this idea became a reality. The results show that the entry characteristics of the material are significantly improved. This technical method can even cool the needle roller or cylindrical roller bearings on the feed roller and has the potential for further optimization.

The above content introduces the advantages of the DEUBLIN rotary joint used in rubber products. In addition, Shenzhen Oudejie Technology specializes in selling new original German imports DEUBLIN rotary joints, and promises to sell products are new original imports, while providing our customers with quotation, selection, product information and other services。