Service Hotline

+1 4152729688

2023-09-21 17:08:14

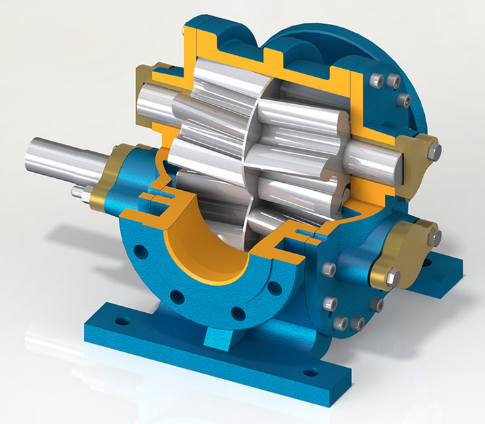

Similar to a straight gear pump,KNOLL helical gear pumpUse a pair of single or double helical (herringbone) gears. Helical gears run more quietly than spur gears, but produce thrust loads that herringbone gears are designed to counteract. These designs are often used to move larger volumes than direct gear pumps. Helical gears produce less pulsation than straight gear pumps because the teeth engage more gently compared to spur gear designs. The spiral Angle is between 15 and 30°.

Both helical and herringbone gear pumps eliminate the problem of trapping fluid in the grid. However, unless a very tight tooth clearance is maintained, these designs introduce leakage losses at the tooth engagement. The higher manufacturing costs associated with herringbone gear pumps must be balanced against their improved performance.

Helical gear pumps are widely used in many industries: food manufacturers use them to move thick pastes and syrups, filter presses, etc.; The petrochemical industry is deploying them in high-pressure metering applications; Engine manufacturers use them to transport oil. They serve as transport pumps. Specially designed for aerospace applications. Hydrodynamic pumps will meet SAE bolt hole requirements.

The above content introduces what is the helical gear pump and what are the problems in the application scenarios of KNOLL helical gear pump. In addition, Shenzhen Oudejie Technology specializes in selling new original German imported KNOLL helical gear pump, and promises to sell products are new original imported, while providing our customers with quotation, selection, product information and other services.