Service Hotline

+1 4152729688

2023-09-21 17:03:36

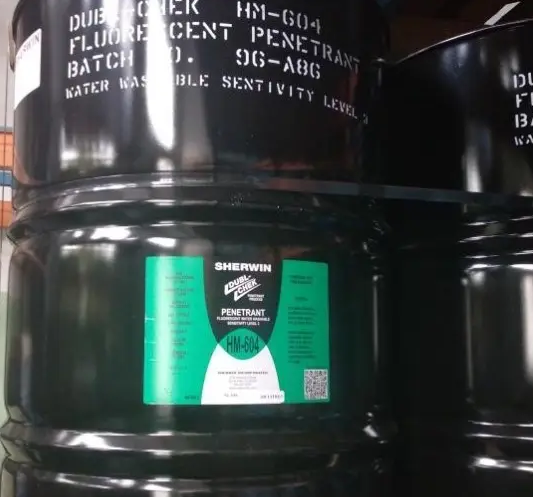

sherwin fluorescent penetrantLiquid penetration testing is required to meet standard practice ASTM E1417. ASTM standards set basic parameters for liquid level, spray, brush, application, residence time, treatment time, and temperature. Each manufacturing company or OEM will have a Local Process Specification (LPS) that also specifies the fluorescent penetration inspection test method for its specific part. Local process codes usually specify drying times, residence times, methods, developer forms, and rinsing requirements.

Fluorescent penetrant detection steps:

1, clean the parts or prepare the surface to be inspected.

2, apply the penetrant to the product, and let it stay while the penetrant "wets" the surface of the part.

3. Remove excess penetrant.

4, the developer will apply the penetrant "imprint" to the surface of the part.

5, check the parts under ultraviolet light, looking for possible cracks or other signs of surface discontinuity.

6. Document instructions.

The above content describes the United States sherwin fluorescent penetrant testing steps are what and penetrant testing implementation standards. In addition, Shenzhen Oudejie Technology specializes in the sale of new original German imports of the United States sherwin fluorescent penetrant, and committed to the sale of products are new original imports, while providing our customers with quotation, selection, product information and other services.