Service Hotline

+1 4152729688

2023-09-21 09:54:07

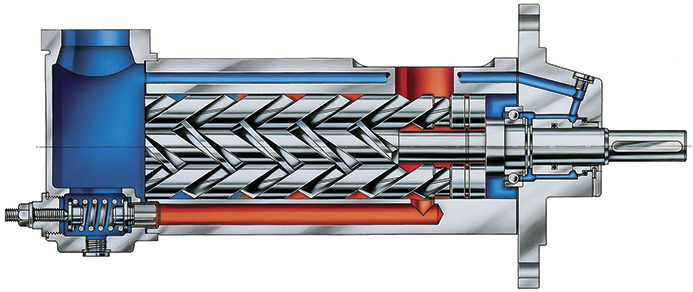

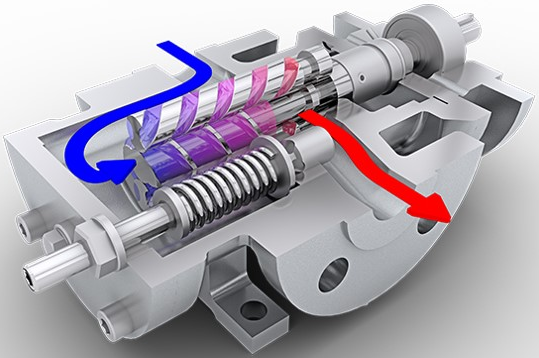

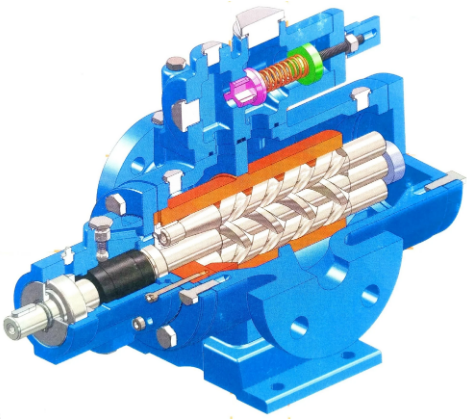

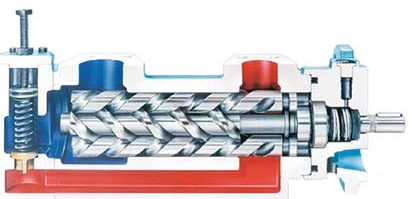

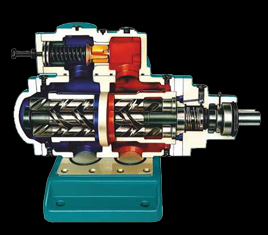

Three screw pump is a rotary positive displacement pump. The displacement effect is generated by the engagement of the three rotating screws and the closed pump housing. The screws are supported radially by sliding contact in the housing, which requires lubrication from the pumped liquid. The three-screw pump series has been thoroughly designed for a wide range of applications. The 3S series consists of 29 different pump sizes with delivery rates of 5-2.900 l/ min@1450 rpm, making it one of the most comprehensive series of three-screw pumps on the market. In addition, individual pump sizes can be used in multiple execution modes, ensuring a high degree of flexibility when specifying pumps for specific system designs.

The three-screw pump series has an external ball bearing design with lifelong lubrication and an expected service life of 30.000 hours. There is a drainage hole between the shaft seal and the bearing to prevent residue accumulation and the bearing is well protected. Ball bearings are not exposed to pumped fluids. The mechanical seal is well lubricated and cooled. Seals are designed to dissipate friction heat effectively.

Three screw pump is a rotary positive displacement pump. The displacement effect is generated by the engagement of the three rotating screws and the closed pump housing. The screws are supported radially by sliding contact in the housing, which requires lubrication from the pumped liquid. The axial support of the main screw is carried out by ball bearings. The pump is equipped with an internal relief valve that limits differential pressure and protects the pump from overpressure. On Alfa Laval 3S pumps, valve Settings can be adjusted according to different opening pressures.

The shell of the three-screw pump is made of ductile iron EN-GJS-400, and the screws are made of nitrided steel 1.7139. High quality mechanical seal with special SIC graphite material as standard. The three-screw pump is available in a variety of models, such as with a free shaft end, as a unit on a bracket base or a vertical base. In addition, in-line and top flange designs are available for every pump size.

Advantages of three screws:

1. Low life cycle cost

2. Long service life, low maintenance cost

3. Compact design

4. High capacity in limited space

Step 5 Be efficient

6. Low noise

7. Low pulsation

8. Pumping without severe turbulence

9. Very good suction conditions (NPSH)

The above content is the working principle of the three screw pump and its advantages, need to know more about the price of imported three screw pump can directly consult Shenzhen Oudejie Technology Co., LTD.