Service Hotline

+1 4152729688

2023-09-21 09:52:24

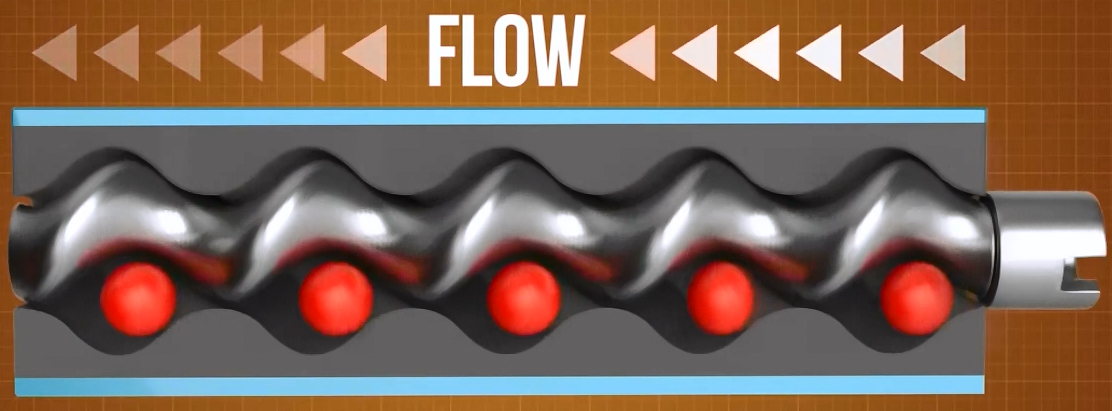

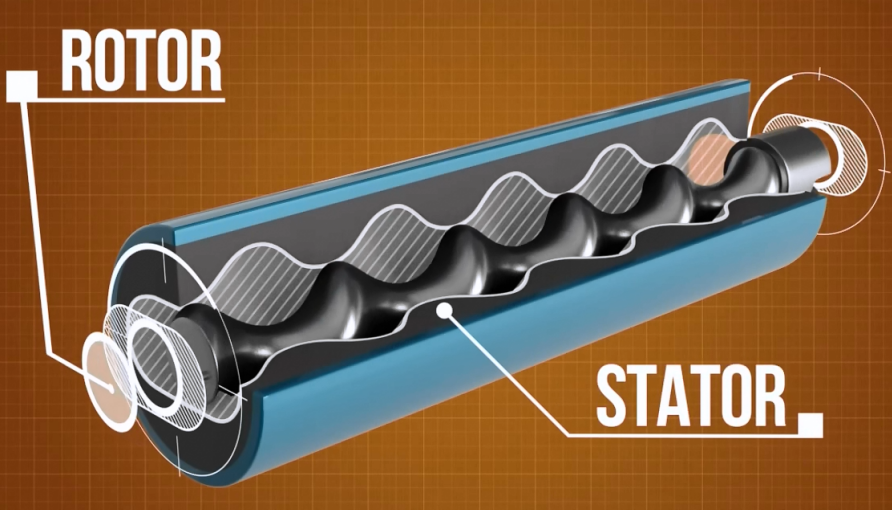

The stator and rotor in the screw pump are a positive displacement pump. They are used to pump mortar, mortar, grout, gypsum and cement. The fixed stator and the rotating part of the rotor are the Yin and Yang of the screw pump. The rotor is a spiral steel shaft that forms the outline of the rubber tube in the conveyor chamber. The stator is a metal tube with an internal molded cavity and is made of either synthetic or natural rubber. When the rotor is triggered, the conveyor chamber moves in the direction of flow. This is how you actually achieve a constant flow of materials. The rotor is similar to the form of a bottle opener, combined with the eccentric rotation movement, and gives its alternative name: eccentric screw pump.

Screw pump stator rotor use:

The stator rotor of the screw pump is pumped with grout, ironed plate, mortar, gypsum or refractory tundish. But rotor stators are also commonly used in the food, pharmaceutical, and cosmetic industries for handling colloidal liquids and liquid systems, and for dispersing or breaking solid particles and aggregates. Rotor stators are also suitable for wood processing and cellulose production, chemical industry, petroleum industry, domestic and industrial wastewater, as well as low-flow, high-lift, agricultural pumping.

The above content is the role and use of screw pump stator and rotor, need to know more about the price of German knoll screw pump can consult Shenzhen Oudejie Technology Co., LTD.