UL/FM fire pumps require what is commonly referred to as "submerged suction" or positive suction pressure before starting. The concept is that the water supply must reach the pump impeller on its own, without the help of the pump. This will ensure that the pump is properly started and ready for operation. For many centrifugal pumps, as little as 3% of the air in the pump casing is enough to prevent the pump from operating properly. Therefore, it is very important to maintain the positive pressure of the pump before starting.

Once started and running, the centrifugal pump can operate under vacuum at negative suction pressure on the suction side of the pump, but there may be air in the pump housing before starting to prevent normal operation.

But even a pump with a proper suction supply may have air, or may not be fully started. We are often asked how to start a pump when it is first installed, or how to start a pump that is used with a water level source below the height of the pump (not submerged suction).

Unless you have a self-priming centrifugal pump (liquid, compressed air, or vacuum), you will need to manually fill it any time it is likely to be filled with air or gas. Starting the centrifugal pump is essential if you want it to operate properly, otherwise the suction pressure generated will not be enough to lift the water, which can lead to problems such as overheating and pump failure. Unfortunately, this is not uncommon, as valves can leak, but the good news is that this process is not difficult to perform!

When starting the centrifugal pump, there are several angles of attack. The purpose of each of these methods is to fill the centrifugal pump housing with liquid before the pump starts (and therefore remove any excess air or gas that can displace water).

Some common methods include:

1, the use of suction source under the pump requires the installation of a bottom valve in the suction pipe, so that the liquid will not be discharged from the pump housing or suction pipe when the pump stops. This requires filling the pump with liquid from the starter pump, pressurized drain line, or other external supply.

2, use suction device above the pump. You need to slowly open the suction isolation valve and then open the vent holes on the suction and discharge lines until the pumped fluid flows out. Once this happens, you can close the vent and vent the isolation valve. Check the valve carefully and then aspirate the isolation valve if needed.

3. Fill the pump with liquid before starting. Many pumps have vents designed for this purpose. With the pump suction pressurized and the discharge isolation valve closed, loosen the vent at the top of the pump housing to allow water to flow out briefly. Close the vents at this time.

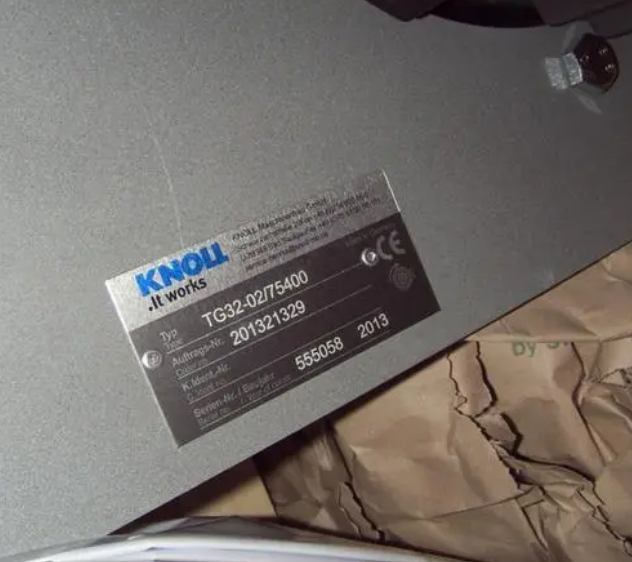

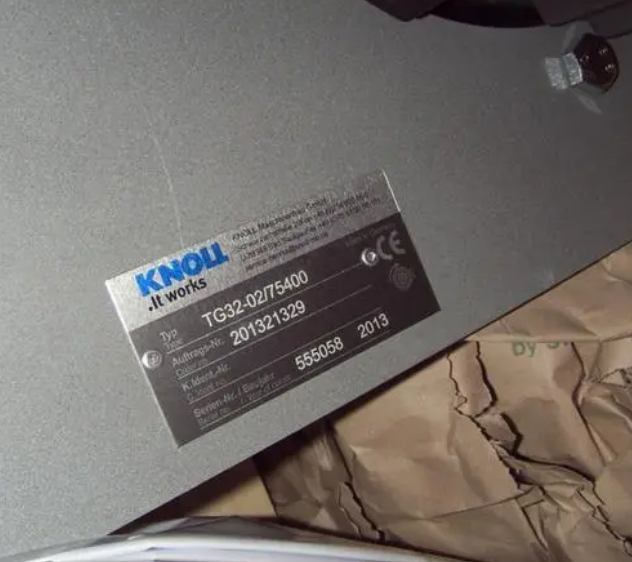

The above content is introducedKNOLLKono centrifugal pumpCan I vacuum it? The problem. In addition, Shenzhen Oudejie Technology specializes in selling new imported KNOLL centrifugal pumps, and promises to sell products are new imported products, while providing our customers with quotation, selection, product information and other services.