Service Hotline

+1 4152729688

2023-09-23 10:37:19

Notes on the life of the rotary joint:

• Side loading of supply lines connected to ports, which may cause joint jumps

• Installing a union with a mounting surface that does not match the spindle specifications will cause runout

• Dead spots in the tool can prevent coolant from flowing through the drawbar, even temporarily

• High operating temperatures

• Running at RPMs that exceed union specs

• Operating at improper hydraulic and coolant pressures below or above specified ranges

• Allow/cause pressure spikes or pulsations which may cause contact seals to vibrate

• Improper residual pressure on the hydraulic seal during rotation, causing premature wear of the seal

• Using incorrect coolant type

• Improper or inadequate filtration, leaving internal seals and bearings susceptible to damage:

• Typically recommended filtration rating is 50 microns or less

• Filter media purity is listed in ISO 4409 -/17/14

• Consider the type of material being processed (for example, glass and cast iron are more abrasive than other types and require finer filtration)

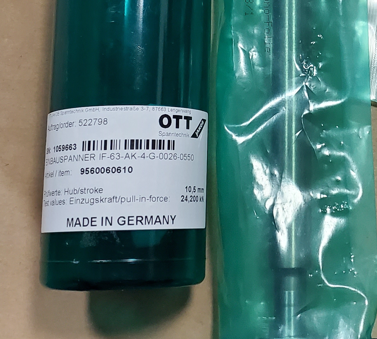

The above content introduces how to avoid spindle failure caused by lathe rotary joints? Problem with OTT-JAKOB rotary joint. In addition, ODJ-Tech Global LLC specializes in selling brand new imported OTT-JAKOB rotary joints, and promises that all products sold are brand new and imported. At the same time, it provides customers with quotations, selections, product information and other services.