Service Hotline

+1 4152729688

2023-09-23 10:40:16

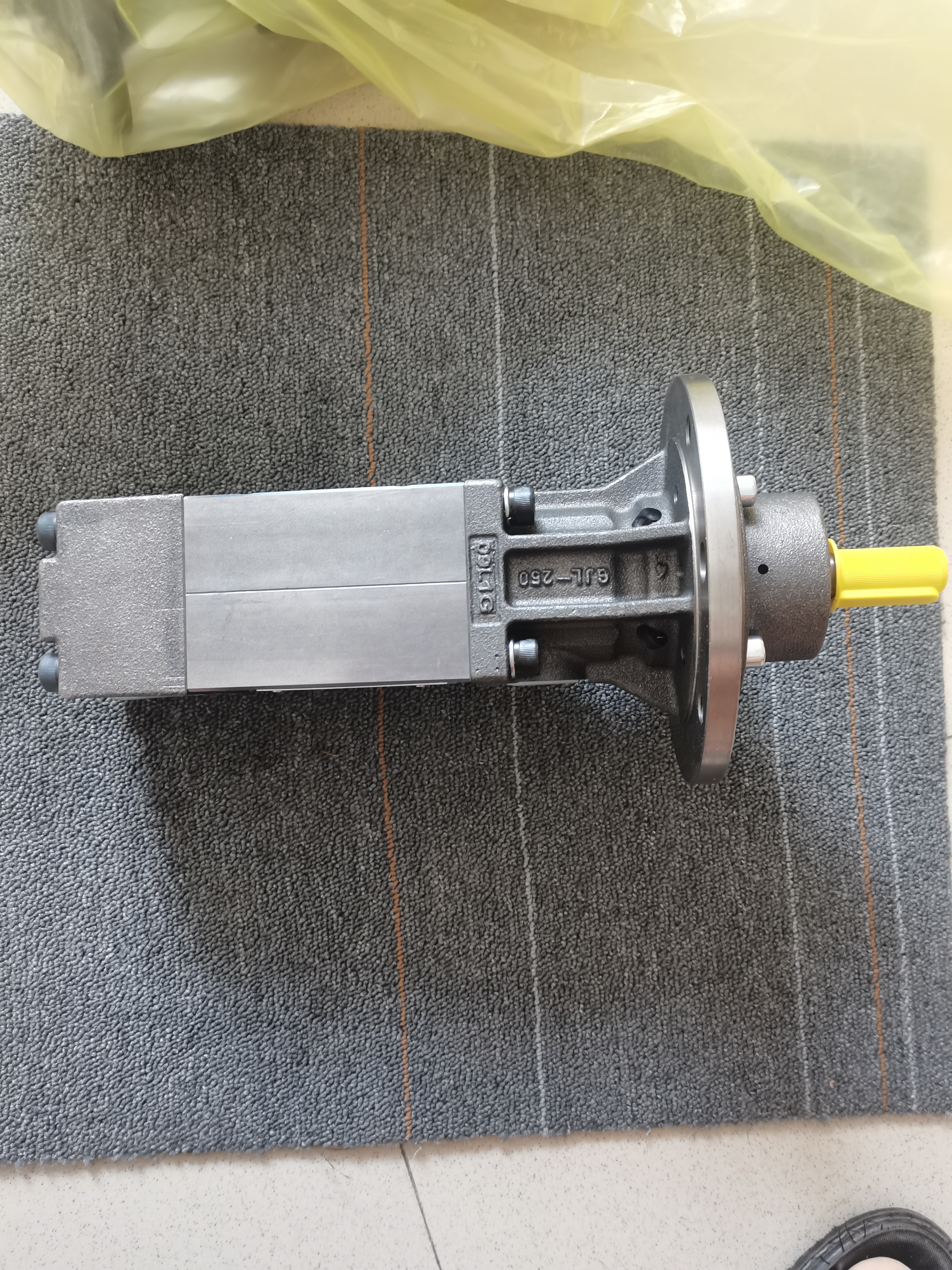

Circulation pump placement

For the correct function of the circulation pump, its correct placement in the heating system is very important. This should be determined by the professional who designed your home or heating system.

However, if you decide to install it yourself, there are basically two ways to install it - either on the return line of cold water to the boiler, or on the hot water discharge line of the boiler. In the past, it was recommended that circulators be placed exclusively on cold water pipes due to the potential for thermal damage. Modern circulators are made of materials that can withstand high temperatures. So if for some reason you cannot install the pump on the return line, you can easily install it at the beginning of the circuit.

It is also worth remembering that the circulation pump should be easily accessible for possible repairs or future setup.

Replace old pump

If you are replacing an old circulation pump in an existing heating system, there are certain parameters that you need to pay attention to when buying a new pump. Most importantly, the new pump should have the same hydraulics, structural length and connecting thread diameter. However, if the circulation pump is replaced due to an increase in the floor heating area or the number of radiators, the parameters will need to be adjusted to suit the new conditions.

Use extreme caution when disassembling an old circulation pump. There may be hot water in the pump and the pressure is high, so there is a risk of burns. Carefully drain the pump before disassembly.

The head of the water pump is not determined by the height of the house, but by the length of the pipe.

Mechanical installation of new pump

If you have chosen a location for your circulating pump and have removed the old pump, it is time to install the new pump. First, assemble the circulation system as follows:

The pump must have valves on both sides so that the flow of water can be stopped while the pump is being repaired or removed. Screw the valve onto the pump threads. Sometimes the faucet can be installed only in the front of the pump and the check valve can be placed in the back of the pump, but for safety and comfort when operating the pump, it is better to have two valves. You can also replace the valve with a cam lock fitting and use an Allen wrench to close it.

A filter must be placed in front of the pump and in the direction indicated by the arrow on the filter, it will catch any dirt and prevent the pump from clogging. Place a check valve after the pump. If the exhaust filter is not part of the pump itself, connect it to the system. All connections must be properly sealed with heated gaskets (preferably rubber). The pump system assembled in this way is installed on the heating system pipes using brass fittings.

The possible locations of the circulation pump are described in the instructions for the specific model, but vertical or horizontal can usually be chosen. However, the direction of flow needs to be maintained at all times, as indicated by the arrow on the pump. At the same time, the switch box must not be located above the water pump, otherwise it will prevent the water pump from properly venting.

NOTE: The pump must be switched off during installation!

Connect the pump to the power supply

After successfully installing the circulation pump, it must be connected to the power supply. The standard voltage for these pumps is 230 V. Check your specific pump.

In addition to the water pump motor itself, depending on the specific model, a control unit and a thermal sensor need to be connected. The circulation pump is a relatively complex electronic device and should therefore only be installed into the network by authorized personnel. Improper wiring can not only cause damage to the pump, but can also cause injury.

A suitable accessory for a circulation pump system is a backup power supply to ensure uninterrupted operation in the event of a power outage.

Install multiple circulators

The number of circulating pumps required is determined by the length of the pipe. Typically, one pump per 80 meters of pipe is sufficient. If you have longer pipes or underfloor heating, it is recommended to install more circulation pumps. Otherwise, the pressure is not enough and the hot water in the heating system will be unevenly distributed.

If you have multiple boilers, you will need at least one pump per boiler. If you have several pumps installed on a boiler, it is recommended to connect a so-called annular space to equalize the pressure in the boiler. If multiple pumps are running simultaneously, excessive pressure may damage the boiler.

Start circulation pump

Before starting up for the first time, it is necessary to bleed some pumps and set the desired mode, respectively. Performance. Non-vented pumps are noisy and may be permanently damaged. However, some modern circulators bleed and adjust automatically.

The above content introduces how to install a circulating pump? KNOLL Kono pump problem. In addition, ODJ-Tech Global LLC specializes in selling brand-new imported KNOLL pumps, and promises that all products sold are brand-new and imported. At the same time, it provides customers with quotations, model selection, product information and other services.