Service Hotline

+1 4152729688

2023-09-23 09:55:18

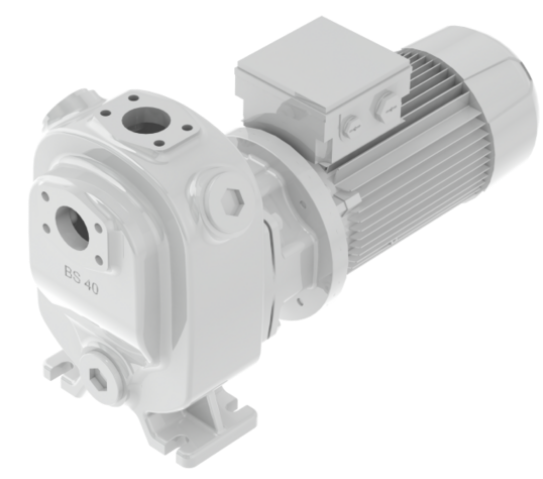

KNOLLKono submersible pumpDesigned for long immersion, it ensures easy installation and years of virtually maintenance-free operation. We recommend choosing a pump with built-in protection. The pump takes care of everything you need without having to buy additional accessories. However, even with the best submersible pump, you can extend its service life by providing good conditions.

First, regular cleaning control

Submersible pumps are used to pump clean water. In general, the more sandy and other abrasive substances in the water, the faster the pump wears out, so it is very important to clean new or dirty Wells and boreholes. For each well pump, the amount of solids allowed is specified by the manufacturer.

Therefore, you should not forget to check your Wells regularly, preferably once every 5 years. This not only ensures the smooth operation of the submersible pump, but also ensures the purity of the pumped water.

Two, beware of water shortage in the well

Submersible well pumps operate at dynamic water levels and must ensure that the water level never falls below the pump level. The pump should be suspended sufficiently deep in the well. If the water level drops too much, the submersible pump may idle and be damaged.

The solution is to use a water level monitoring probe or a pump with built-in anti-drying protection to stop the water in the well in case of failure.

Third, the correct depth of immersion

It is very important to install the submersible pump at the correct depth, not only to prevent dry rotation, but also to prevent damage to the pump due to high water pressure. When submerged at deeper depths, the water column exerts a higher pressure on the pump, which affects its tightness. If the pump is immersed deeper than the designed depth, the internal parts of the pump may be damaged by water seepage.

If there is no water in the well, it may not be installed at the right depth. However, before sending the pump deeper into the borehole, it is first necessary to carefully check the correct diving depth of the pump. A lack of water can also be caused by a small well capacity, so find the cause first.

Four, well pump cooling

Cooling the submersible pump is another reason it's important to keep an eye on the water level in the well. There is enough water flow around the pump (at least 0.15m /s) to provide it with the necessary cooling so that the motor does not overheat. The optimal space between the pump layer and the borehole wall is at least 10 mm, a limitation that also prevents mechanical damage.

If the necessary cooling cannot be guaranteed by water flow, the same effect can be achieved by installing a cooling jacket.

Voltage fluctuations in the network

The well pump operates within a certain voltage range. However, the voltage in the network is not always constant and fluctuates, which can lead to more frequent pump downtime and engine damage.

Turn on and off your submersible pump frequently

The frequent start and stop of the submersible pump, whether due to insufficient voltage or water shortage, will overload the motor and pump contactors, thus greatly shortening their service life. For each type of well pump, there is a recommended maximum number of starts, which should not be exceeded for protection purposes. On the other hand, it's also not a good idea to turn it off for long periods of time. The submersible pump motor needs to be started at least once a year to prevent jamming.

7. Electrical and mechanical load on the pump

Inadequate cooling, fluctuating power supply voltages, frequent starts and stops, and prolonged pump operation at maximum flow rates all lead to high electrical and mechanical stresses that accelerate wear and shorten service life. It is important to minimize all these disadvantages to achieve smooth operation. Your pump must be selected so that it is closest to the optimal (peak) efficiency point, while at maximum flow it should only operate minimally.

Eight, well pump antifreeze

Submersible pumps can be used all year round as long as they have operating conditions. However, if you do not use the water source during the winter, you must freeze the submersible pump and freeze the borehole or well at the same time.

The submersible drilling pump is not freeze-resistant, so to be freeze-resistant, power it off, pull it out of the borehole/well, drain it and store it in a safe place where it will not freeze. The water source itself is then carefully antifreeze so that it is not contaminated by heavy rains and snowmelt, even if it is only used as a source of domestic water. When restarted, large amounts of sandy material and other abrasives in contaminated water may damage the pump. If you are unsure of the water quality, it is best to analyze it before the season or clean the well just in case.

9. Regular maintenance

Regular submersible pump servicing is an excellent way to ensure that your pump is always in top condition. It also includes the replacement of worn parts (especially seals). The frequency may vary depending on the flow rate, the presence of solids, and well conditions, but it is generally recommended that submersible pumps be serviced every 3 years.

The above content describes how to extend the service life of the submersible pump. KNOLL Kono submersible pump problem. In addition, Shenzhen Oudejie Technology specializes in the sale of new imported KNOLL submersible pump, and promises to sell products are new imported original, while providing our customers with quotation, selection, product information and other services.