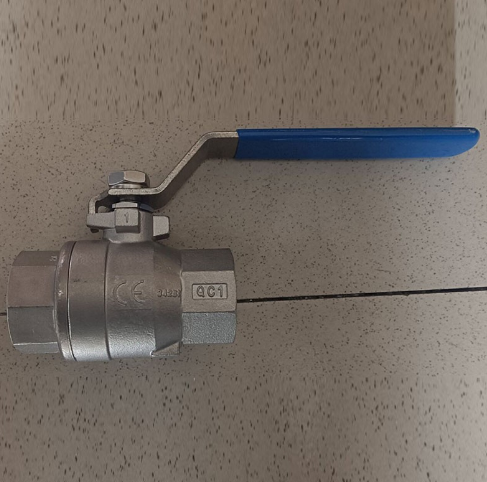

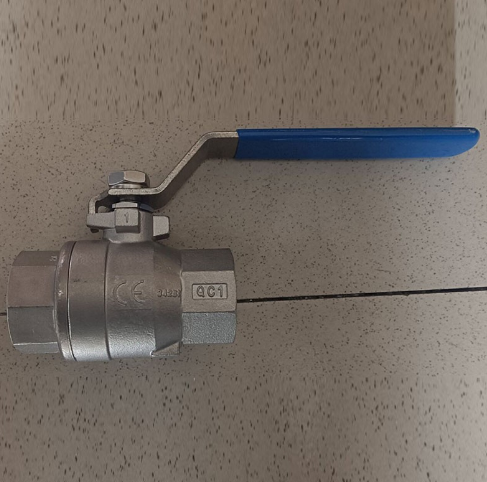

GermanyBeeBall valveUsed to close and control the flow of liquids or air and non-corrosive gases. Therefore, it is an important part of the heating or cooling system. Flow is controlled by a rotating ball. The undeniable advantage of ball valves is their excellent sealing performance.

There are two types - t double and three way ball valves. Another category is the close and control category, where the close is usually full flow, while the control has a special plug-in for linearizing the close process.

As the name suggests, the stop valve is used to cut off the flow of liquid. These are usually two-way valves. With these valves, there is no need to linearize the closing process because you want to shut off the flow as quickly as possible. In addition, for three-way full-flow ball valves, there are confluence valves and diverter valves, the difference lies in the direction of the medium flow.

Control ball valve with linearization plug-in. This is important for flow control, so the percentage of rotation of the control actuator corresponds to the percentage of valve open and the percentage of fluid flow. Ball valves can be made of brass, stainless steel or plastic (PVC).

In addition to the choice of material, there are a variety of ways to start the valve - this can be done manually via the handle, or with an automatic/remote electric or pneumatic actuator.

Classification of ball valves:

1. Ball valve with drain port

• Unlike conventional ball valves with threaded or flanged designs, ball valves with discharge have an additional discharge cock on the valve side. Therefore, drain ball valves are used to close pipes in the same way as traditional ball valves, but side drainage makes loop drainage possible.

• Users use this feature frequently, for example, when they need to drain their garden water supply before winter.

Two, control the ball valve

• Thanks to specially shaped inserts inside the valve, the control ball valve can regulate - that is, reduce - the flow rate and ensure an equal percentage of the flow characteristics.

• Control ball valve with linearization plug-in. This is important for fluid flow control, so the percentage of rotation of the control actuator corresponds to the percentage of valve open and the percentage of fluid flow.

• For trouble-free operation and long service life of the product, it is recommended to always place a filter in front of the control ball valve to filter out any solids that may damage the valve closing mechanism.

• The control ball valve is installed on the pipeline along the direction of the flow arrow, and the lever is controlled by the scale, which can easily and accurately control the flow rate.

Three, switch ball valve

• Switching ball valves are usually two-way or three-way, and some manufacturers even produce six-way valves. Switching ball valves are used to open and close hot and cold water systems.

• The on-off ball valve is controlled by a rotary actuator, which is controlled by an on/off signal. The valve opens counterclockwise and closes clockwise.

4. Ball valve with manual handle

• Manually controlled ball valves are suitable for use as stop valves in common heating and cooling applications. They can be used for drinking water, domestic water or DHW water, as well as a variety of other non-corrosive media. Most of them are maintenance-free.

What is the role of Bee ball valve introduced above? The classification of ball valves. In addition, Shenzhen Oudejie Technology specializes in selling new imported Bee ball valves, and promises to sell products are new imported products, while providing our customers with quotation, selection, product information and other services.