Service Hotline

+1 4152729688

2023-09-23 09:44:39

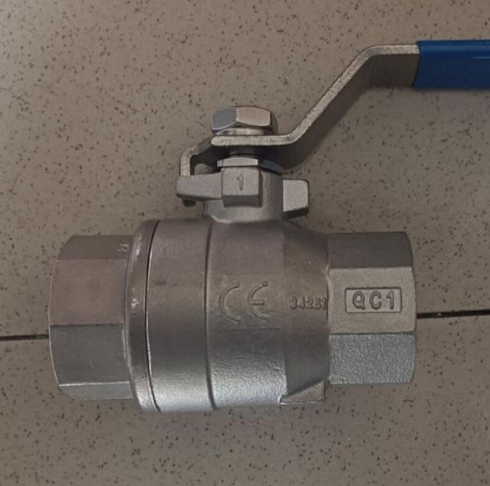

What isBeeBall valve?

Ball valves are a staple of industrial piping systems thanks to their right-angle turn function, which makes it exceptionally easy to control fluid flow - either manually or in automated systems.

Ball valves allow for maximum flow and minimum pressure drop, and require little maintenance. Depending on the number of exposed holes (hollowed out in the center of the ball), the fluid flow rate is limited or allowed to flow completely.

What is a high pressure ball valve?

High pressure ball valves are used to control the flow of high pressure media in fully open and fully closed positions. They are designed to handle liquids, gases or corrosive liquids at increased pressure flows than normal. High-pressure ball valves are commonly used in industrial applications such as pharmaceuticals, hydraulics, oil and gas, and cosmetics.

High pressure ball valves are ideal for measuring flow pressures above 3,000 psi (207 bar). Some high pressure valves, such as three-way ball valves, can actually handle flows greater than 15,000 psi.

High pressure ball valves provide tighter closures designed to withstand the wear associated with high pressure applications and are suitable for critical operations in many industrial environments.

High pressure ball valve application

High pressure ball valves are used in a range of applications using systems that require reliable power shutdown. The choice of these applications is:

• Chemical and petrochemical industries

• Offshore, aquatic, high-pressure cleaning systems

• Hydraulic system

• Mining

• Gas pipeline

• Agricultural machinery

The water industry is where you are most likely to encounter high pressure ball valves, they are also known as hydraulic ball valves.

In the oil and gas industry, high pressure ball valves are used to manage operations at extreme temperatures. This is because they are excellent at handling cold and high temperature operations.

They are also frequently used in the pharmaceutical, food and cosmetic industries because they require leak-proof, durable high-pressure ball valves to regulate the flow of sensitive and corrosive media. Stainless steel or carbon steel ball valves are favored in these types of industries because of their resistance to corrosion and wear.

What is a low pressure ball valve?

Low pressure ball valves are made of carbon steel, stainless steel and brass. The standard material application for low pressure ball valves is stainless steel because of its high corrosion resistance.

Low pressure ball valves work in the same way as high pressure ball valves - by controlling the flow of liquid or gas - but can only withstand pressures up to 2,000 psi (138 bar). They are also primarily used in temperatures ranging from -29°C to +150°C. The higher the temperature, the lower the pressure the ball valve can withstand. Low pressure ball valve according to the channel flow can be divided into full diameter ball valve and reduced diameter ball valve.

What is the difference between high pressure ball valves and low pressure ball valves? Bee ball valve problem. In addition, Shenzhen Oudejie Technology specializes in selling new imported Bee ball valves, and promises to sell products are new imported products, while providing our customers with quotation, selection, product information and other services.