Service Hotline

+1 4152729688

2023-09-22 15:27:48

NanostoneNano Stone ceramic membraneFor industrial applications including oil/water separation, catalyst recovery, textile needs, wastewater and even alkaline cleaning solution recovery. The use of ceramic ultrafiltration membranes at the industrial level in the treatment and processing of various liquids, including those of organic origin, has increased greatly. In addition to selecting the most suitable membrane material and operating conditions, the right membrane cleaning procedure is also necessary to reduce contamination and extend the life of the membrane. This review summarizes the currently available and practiced non-reagent and in-situ cleaning methods of ceramic membranes for the treatment of organic liquids resulting in organic contamination. Backwash, backwash and ultrasonic are the most commonly used physical methods for reversible scaling treatment. At the same time, it is recommended to use an alkali such as sodium hydroxide, acid or strong oxidant to clean irreversible dirt treatment.

Nano Stone ceramic ultrafiltration membrane with a ceramic urea (methyl) aldehyde resin membrane system has been applied to the treatment of industrial scale crew, ceramic ultrafiltration membrane has a good removal effect on oil and COD. And optimizing the operating conditions can effectively alleviate the membrane pollution, and the service life of the membrane tube is greatly extended.

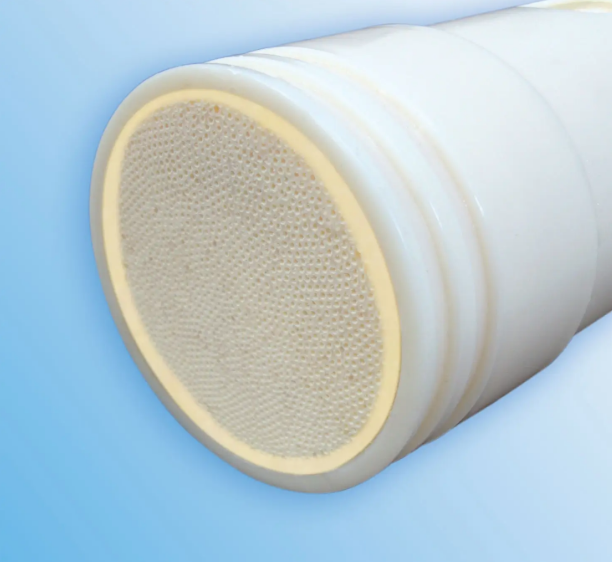

Ceramic filters (membranes) filter, separate and purify wastewater for reuse in the process or for safe discharge into the sewer. It is an artificial film made of inorganic materials such as alumina, titanium dioxide, zirconia or silicon carbide. Multiple layers of ceramic membrane material are applied to produce tubular membrane elements, also known as ceramic elements. Ceramic microfilters use a cross-flow design in which most of the feed flow passes through the filter surface in a tangential direction rather than entering the filter. It also has excellent thermal stability, which makes it suitable for high temperature operation and can be used for separation in the presence of corrosive media such as acids and strong solvents. The element has multiple channels of different diameters (porosity) to supply water through, with porosity ranging from 0.05 to 0.2 microns.

The above content introduces what Nanostone ceramic ultrafiltration membrane application areas are, and what industries are used. In addition, Shenzhen Oudejie Technology specializes in selling new original German imported Nanostone ceramic ultrafiltration membrane, and promises to sell products are new original imported, while providing our customers with quotation, selection, product information and other services.