Service Hotline

+1 4152729688

2023-09-22 11:44:59

Centrifugal blowerUsed where air flow is required. Any fan with a high pressure ratio is called a blower. The main use of blowers is in processes that require continuous and steady air flow, such as pneumatic conveying systems. In the selection of blowers, centrifugal blowers have a number of advantages over other types due to their wide working range and fast speed. The change of centrifugal blower is the air flow rate, blower type, blower size and working pressure. Regardless of the changes, centrifugal blowers can be customized and adjusted to suit any type of industrial application.

Clean air treatment

Air flow is a critical part of all industrial operations as it is a way to provide comfortable working conditions and remove toxic or harmful fumes. Centrifugal blowers for industrial air movement include backward bending, backward tilting and radial.

Industrial exhaust blowers or fans handle clean dry gases or light particulate saturated gases. This type of ventilation blower is designed for heavy industrial operations where fresh air must be used to replace exhaust gases.

Dust load

Dust collection centrifugal fans and blowers are part of dust collection systems that help improve air quality and create safe breathing conditions. Centrifugal dust removal blowers capture, collect and move particulate air through an air washing system.

This type of centrifugal blower comes in a variety of configurations. They may be part of a hood system above a dust-contaminated workspace, or they may be the starting part of an air filtration system, such as a bag dust collector, a trap, or some kind of plumbing system.

Pneumatic material handling

The essence of pneumatic material handling systems is to maintain constant pressure throughout the system to prevent shedding and clogging. Pneumatic system can transport a variety of materials; This includes sand, particles, debris and coal.

Pneumatic systems use an array of feeders, fans, blowers, pipes and filters to move materials. The main feature of choosing the right centrifugal blower for a pneumatic system is the density of the material, which is the factor that determines the blade type, drive and any necessary accessories.

Saturated fan

Saturated air is air that has been made wet by moisture or some form of gas. Due to the particle content, the air in these conditions is usually heavier and requires a more robust centrifugal blower. The moisture content in the air requires the use of centrifugal blowers made of stainless steel and having some form of coating, such as epoxy resin.

The biggest challenge with saturated air is corrosion, which can seriously damage blowers. All centrifugal fans and blowers for such applications are made of corrosion-resistant metal and may contain some form of protective coating. Precision designed and well-planned systems reduce repair and maintenance costs and extend the life of blowers.

High temperature application

Heat treatment, stress relief, industrial stoves and ovens use convection to circulate hot air. Centrifugal blowers and fans for such operations need to be highly elastic, durable and durable to withstand high temperature conditions.

Regardless of the design and engineering of centrifugal fans and blowers for high temperature applications, they are bound to wear out and fail due to conditions. With this in mind, centrifugal fans for high temperature applications must be closely monitored and maintained to prevent catastrophic failures.

Specially designed plug blowers and fans are most commonly used in high temperature applications. Plug blowers are designed to transport large amounts of air at low static pressure. They are available in a variety of wheel configurations and materials.

Dairy product processing

The main function of centrifugal blowers for the dairy industry is to move and recycle air in processing plants. Centrifugal blowers used in the dairy industry must comply with Food and Drug Administration (FDA) regulations applicable to any form of food processing equipment. In addition to being used as a means of cleaning and recirculating air, centrifugal blowers for the dairy industry are also used as part of the drying process for cheese and dairy by-products.

incinerator

A typical use of incineration is to dispose of waste by burning it. The centrifugal blower used in incinerator is designed to meet the requirements of gas volume and pressure in incinerator. The forced ventilation system uses high-pressure centrifugal blowers to feed air into the incinerator. On the exhaust side of the incinerator, an induced draft fan is used.

In fluidized bed furnaces where sludge is incinerated, a multistage blower system is used because of the high pressure required to provide a proper air supply. These specially designed blowers are designed to prevent any negative effects of sludge or decaying gases.

The standard of blowers for this application is very high and is becoming more stringent as environmental concerns continue to increase. All manufacturers work hard to ensure that their equipment meets the requirements of the Air Motion and Control Association (AMCA) and Air Quality Control.

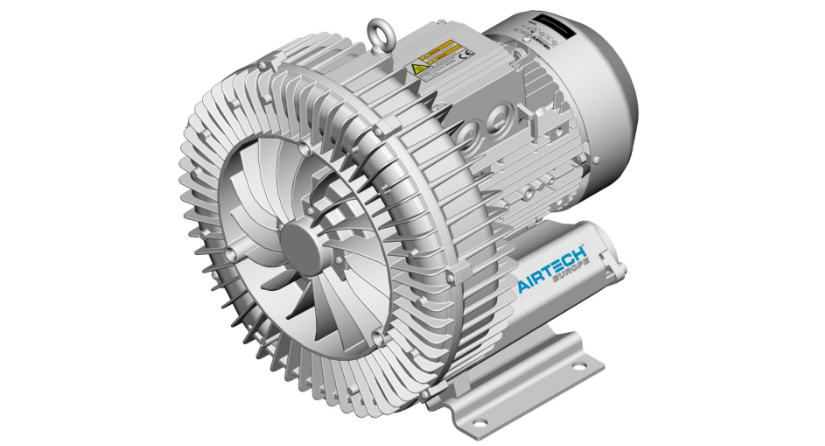

What is the purpose of the AIRTECH centrifugal blower introduced above? The problem. In addition, Shenzhen Oudejie Technology specializes in the sale of new imported AIRTECH centrifugal blowers, and promises to sell products are new imported, while providing our customers with quotation, selection, product information and other services.