Service Hotline

+1 4152729688

2023-09-22 11:43:59

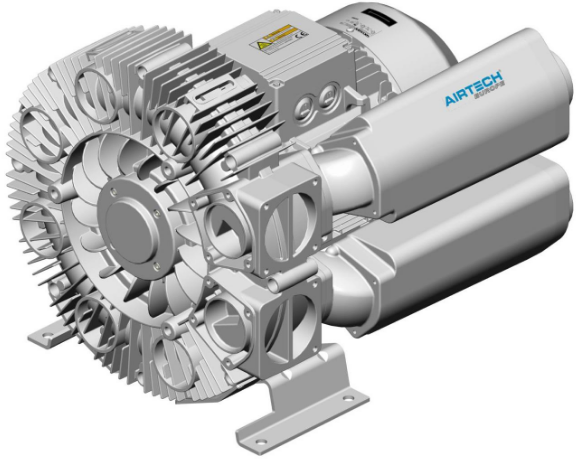

Centrifugal blowerIs a motor or pump that moves air using the centrifugal force generated by the rotation of the impeller, which draws air or fluid into the blower and pushes it out of the outlet of the blower. They consist of an impeller with a series of blades mounted on a central hub connected to the fan shaft, a housing and a drive mechanism.

The drive design of the centrifugal blower (which can be belt driven or direct driven) determines the speed at which the impeller rotates. The speed and efficiency of centrifugal blowers make them suitable for a wide range of applications, including various types of dryers to HVAC systems.

The Angle of a centrifugal blower blade determines its efficiency and effectiveness, or the speed at which it moves air through the system. The three variants of blade Angle are forward curved, backward curved, and radial.

Centrifugal blower advantages:

1. Low maintenance

The most significant factor of centrifugal blowers is the low maintenance cost. After spending thousands of dollars on equipment repairs and installation, the low cost of centrifugal blowers helps maintain and control operating costs.

When using other methods of air circulation, it is important to check frequently for the accumulation of dust and dirt. This is not necessary for industrial centrifugal blowers. Only a small vacuum cleaner is needed to clean the motor and vents. Centrifugal blowers have a somewhat simple modular design that makes them easy to maintain and repair.

2. Energy saving

For any form of industrial equipment, operational efficiency ensures lower costs and increased productivity. The constant and uniform air flow from the centrifugal blower produces energy with a static efficiency of 84%, which is the ideal standard for maintaining a large airflow system.

3. Versatility

One of the main reasons centrifugal blowers are so widely used is their ability to adapt, adjust and configure to meet the needs of any industrial operation. Centrifugal blowers are capable of operating in any airflow system and can be adjusted to meet changing and growing operational needs.

Centrifugal fans and blowers can be found in any type of industry, from paper mills to auto plants. In each case, they serve a different purpose with as much efficiency as possible.

4. Durability

Many modern manufacturing processes require equipment that can withstand the hazards and harsh conditions created by the operating environment. Centrifugal blowers and fans are designed to operate in corrosive, toxic, high temperature and high humidity conditions. Each type of centrifugal blower is carefully designed to meet the demands of manufacturing conditions and provide superior performance.

What is the centrifugal blower introduced above? What are the advantages of AIRTECH centrifugal blowers? The problem. In addition, Shenzhen Oudejie Technology specializes in the sale of new imported AIRTECH centrifugal blowers, and promises to sell products are new imported, while providing our customers with quotation, selection, product information and other services.