Service Hotline

+1 4152729688

2023-09-22 11:28:35

One, 12V pump

These pumps operate at 12 V DC with a maximum flow rate of 330 GPH. It consists of a crocodile clip, battery cable and an on/off switch for easy operation. The minimum height of the water pumped using the suction filter is 1/8 inch and the maximum height of the water lifted is 40 feet. 3/4 inch garden hose adapter, 6 foot suction hose, washers for replacement and an additional impeller are available at both exits and entrances. Because of its light weight, it can be carried. In this case, the handle can be attached to the body for ease of use.

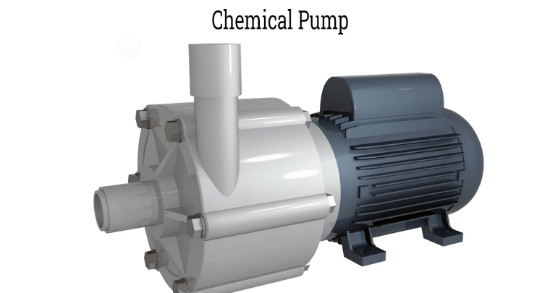

Second, chemical pump

Chemical pumps are designed to pump chemicals in corrosion-resistant materials and are suitable for handling corrosive and abrasive industrial liquids such as paints, fuels, solvents, bleach, etc. Pumps that collide with chemicals can cause them to become brittle or dissolve, expand, and eventually leak and fail. Special consideration needs to be given to the material of the chemical delivery pump, as well as the concentration and temperature of the fluid being handled. Whenever a stoichiometric pump is required, a pump for tank-to-tank transfer or barrel emptying can be tested on the pump.

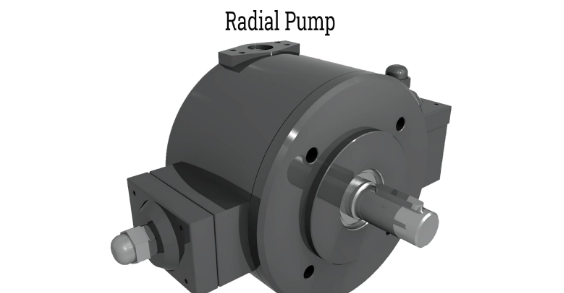

Three, radial pump

In a radial centrifugal pump, the fluid flows out of the impeller after rotating 90 degrees relative to the suction inlet. Many centrifugal pumps fall into this category. The fluid enters through the horizontal suction flange and leaves through the vertical discharge flange. The discharge will be perpendicular to the pump shaft. This design is often used when there are flow limitations and the need to increase discharge pressure. Therefore, the radial design is low flow and high pressure pump. Most pumps used in the gas and oil industry fall into this category.

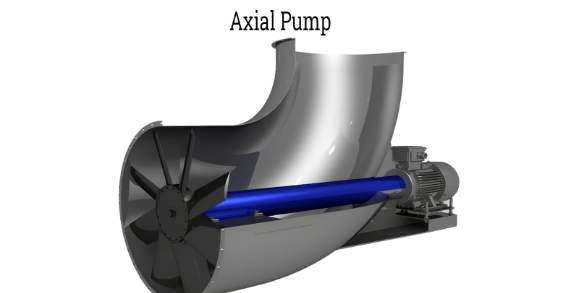

Four, axial flow pump

In axial flow centrifugal pumps, the fluid can move parallel to the axis. This process works in the same way as the propellant. The most important application of this pump is where the flow rate is large and the head is small. For example, they are commonly found in water circulation pumps and dewatering pumps.

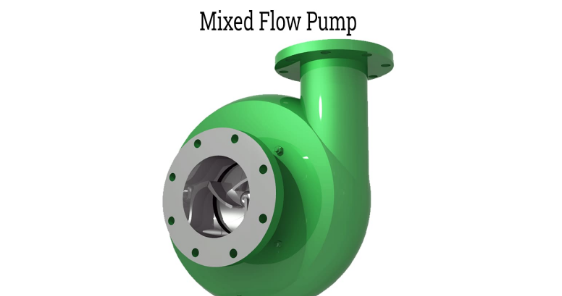

Five, mixing pump

As the name suggests, in a mixed-flow centrifugal pump, the fluid flow mixes axial and radial characteristics. This is a trade-off between radial and axial pumps. The mixing pump operates at a greater flow rate and has a considerable increase in head.

Six, single suction pump

In a single-suction centrifugal pump, the flow of the fluid goes directly into the inlet, and the rest of the liquid immediately flows into the impeller eye, which is the inlet of the impeller. As the water leaves the impeller, centrifugal force creates pressure.

Seven, double suction pump

When the flow rate is too high, the single suction is not enough. In this case, a double suction centrifugal pump is used. The impeller of the pump is carefully designed so that fluid can enter from all sides, compared to the one side under normal conditions. Still, the name "double suck" should not be confused. Even in double suction pump designs, there is only one flange for discharge and suction. The difference lies in the design of the casing and impeller.

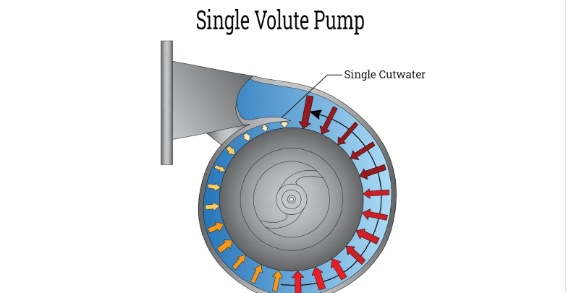

Eight, single volute pump

In centrifugal pumps with a single volute, fluid is discharged from the impeller and enters a volute that is completely wrapped around the impeller. This single volute has a water distribution point that delivers the fluid flow to the outlet of the pump. Most of the centrifugal pumps in oil refineries are single volute type.

9. Garbage pump

These pumps are portable pumps and are commonly used for dewatering applications. They plan to extract large amounts of water containing hard and soft solids such as mud, twigs, leaves, sand and sludge. Most garbage pumps are heavy-duty portable centrifugal pumps that have larger discharge ports and deeper impeller blades than other pumps. Garbage pumps are capable of handling materials with some suspended particles that clog other centrifugal pumps and can move hundreds or even thousands of gallons per minute. The material entering the pump is not grounded in the impurity pump. They are designed with large discharge ports, pump housing and deep impeller veins. Pumps can be made of cast iron, steel, aluminum and stainless steel. Most of these pumps have a roll cage.

A semi-garbage pump is a garbage pump with a small opening. They are not suitable for handling large solids or high solids concentrations. Therefore, ordinary refuse pumps are more suitable for applications that require strict pumping of solid slurry or water. There are four types of impurity pumps: injection pumps, screw pumps, sanitary pumps and positive displacement pumps.

• Injection pumps are used to handle materials that require precise flow rates at precise intervals. Infusion pumps process liquids under highly controlled pressure, and extraction pumps remove liquids, which are the two types of injection pumps.

Sanitary waste pumps are pumps used in screw waste pump applications that require a high level of sanitation, such as breweries, food and biotechnology companies. This type of pump is also capable of moving gauges and mud solutions.

• Screw pumps are used to transport fluids and mud with suspended solids. Fluid is drawn from one side of the pump and discharged from the other side before entering the tank or passing through the pipe. Cavity pumps can properly transport viscous fluids and materials with slower flow rates from these pumps and can flow continuously.

• Positive displacement pumps use pistons, diaphragms, gears and other devices to pump fluid. They can also be moved by the vacuum created when fluid is pumped into a fixed chamber and then out again, creating a vacuum that sucks in other fluids. Positive displacement pumps are best when it comes to viscous liquids under great pressure.

Ten, vertical pump

They are also known as deep well turbopump. These are vertical axis or mixed-flow centrifugal pumps that include a series of fixed bowls and rotating impellers to handle the guide blades. Vertical pumps are used as long as the pumping level is below the volute centrifugal pump limit. Vertical pumps are costly and more complex to refurbish and install. The design of the indenter mainly depends on the length of the impeller and its speed. It is not suitable to design only one impeller indenter. The different types of vertical pumps are:

• Pipeline pump

• barrel pump

• Vertical column pump

• Submersible pump

• Deep well pump

• Can pump

Some more or less similar types of pumps are vertical pumps, vertical turbine pumps, process pumps, and industrial pumps.

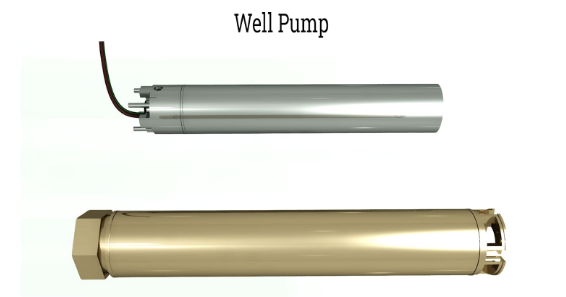

11. Well pump

The well pump is the heart of the well system. They pump water upward into the home or into a designated water supply system. Jet pumps and submersible pumps are the most popular pumps today. Both pumps rely on centrifugal force to push the water upward. The rotating rotor, also known as the impeller, creates a vacuum that forces water up through the well casing and into the distribution system. The type of suitable well pump required for a well system should depend on the amount of water required by each home and the depth of the well.

The jet pump is placed on the ground, pumped from the ground through the suction pipe, and vacuum is generated by the impeller. The impeller drives the water through a small nozzle. It is necessary to first fill the jet pump with flowing water when pumping water. Shallow well jet pumps are used in Wells with a depth of 25 feet, while deep well jet pumps, on the other hand, typically cover a depth of 150 feet.

Submersible well pumps have a wider depth range and can be used in Wells as shallow as 25 feet and as deep as 400 feet. As the name suggests, submersible pumps are submerged in Wells below the water level. Most of its energy is used to push water up, rather than drawing water from above like a jet well pump.

Submersibles are cylindrical, and they consist of a pump motor and several impellers for pushing water up the pump and into the downcomer. Due to their durability, efficiency, and versatility of well depth, most modern well systems use submersible pumps rather than some other pumps.

The above content introduces what types of KNOLL centrifugal pumps are divided into? Type of centrifugal pump problem. In addition, Shenzhen Oudejie Technology specializes in selling new imported KNOLL centrifugal pumps, and promises to sell products are new imported products, while providing our customers with quotation, selection, product information and other services.