Like all nondestructive testing methods, the results of SHERWIN osmotic test are only reliable if the test is accurate and consistent.

1, surface preparation: The test surface is clean, dry and free of any dirt, grease, paint or other materials that may interfere with the inspection.

2, penetrant application: Liquid penetrant can be applied to the test surface by dipping, brushing or spraying.

3, penetrant residence time: Penetrant needs to have enough time to enter any discontinuity. The residence time will be determined by several parameters, including the type of penetrant, the type of developer, and the type of defect to be found.

4, excess penetrant removal: the penetrant remaining on the surface needs to be carefully removed, while not interfering with the penetrant penetrating into any discontinuity. Depending on the type of removal method, it may be necessary to dry the parts in an oven after removing excess penetrant.

5, developer application: coated with a thin and uniform developer, the penetration agent at the discontinuity is extracted to the surface to form an indication. Development times will vary depending on penetrant, developer type, and defect type.

6, inspection: Parts are evaluated under appropriate lighting conditions to obtain instructions and appropriate steps are taken to interpret and document any findings.

7, after cleaning: cleaning parts after inspection to remove any residual developer and penetrant.

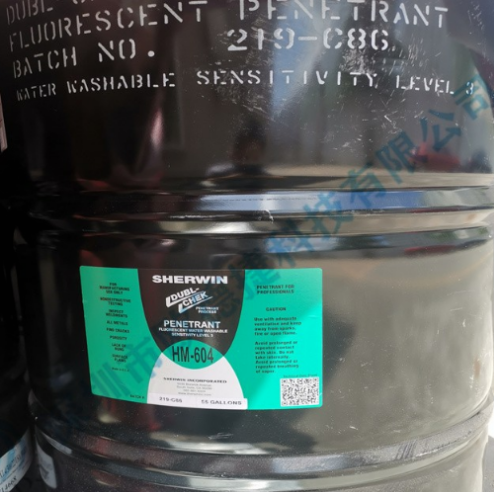

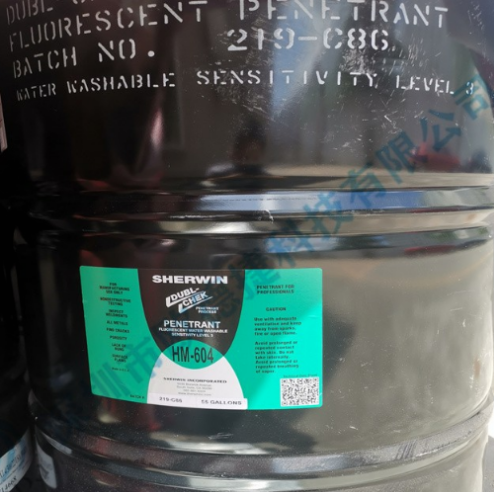

The above describes how SHERWIN penetrant performs liquid penetration testing. In addition, Shenzhen Oudejie Technology specializes in the sale of new imported SHERWIN Sherwin penetrant, and promises to sell products are new imported original, while providing our customers with quotation, selection, product information and other services.