1. Initial cleaning:

Before applying the penetrant to the surface of the relevant material, it must be ensured that the surface is free of any contamination that could fill defects or misindicate defects, such as paint, oil, dirt or scale. Chemical treatment with solvents or reactants removes unwanted contaminants from surfaces and ensures good permeability when using penetrants. It is also sometimes dried in ovens at temperatures up to 100° C and cooled to 40° C. Sandblasting to remove paint from the surface prior to the FPI process may mask (apply material) cracks and render the penetrant ineffective. Even if the part has passed the previous FPI operation, it must be cleaned again. Most penetrants are incompatible and thus hinder any attempt to identify defects that have been penetrated by any other penetrant. This cleaning process is critical because if the part surface is not properly prepared to receive the penetrant, the defective product may be transferred for further processing. This can result in wasted time and money in rework, overprocessing, and even scrapping finished parts at final inspection.

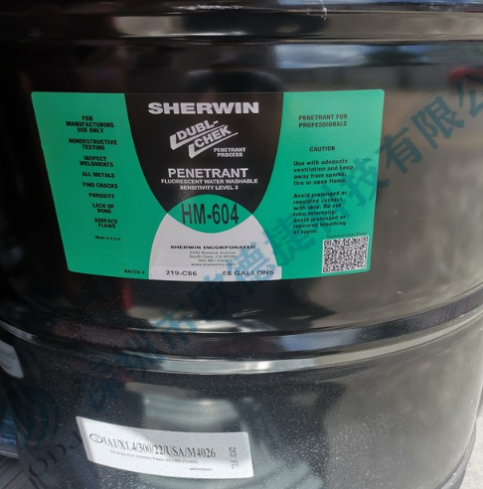

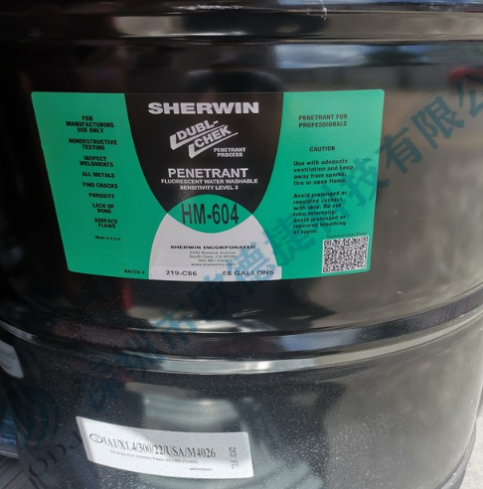

2, penetration application:

The fluorescent penetrant is applied to the surface and time is allowed to penetrate into the defect or defect of the material. The process of waiting for the penetrant to penetrate the defect is called the residence time. The stay time varies depending on the material, the size of the indication to be identified, and the requirements/standards, but is usually less than 30 minutes. It takes less time to penetrate larger defects because the penetrant is able to penetrate faster. The opposite is true for smaller defects/defects.

3, remove excessive penetrant:

After a certain residence time has passed, the penetrant is removed from the outer surface of the material. This highly controlled process is necessary to ensure that the penetrant is removed only from the surface of the material and not from inside any identified defects. A variety of chemicals can be used for such processes and vary depending on the specific penetrant type. Depending on the process sequence, when the emulsification process is used, an intermediate "emulsification" step including post-washing takes place here. Important: No matter which method is used, the penetrant will remain in the crack. Usually, the cleaner is applied to a lint-free cloth used to carefully clean the surface.

4. Developer application:

After the excess penetrant is removed, the contrast developer can be applied to the surface. This is the background where defects can be more easily detected. The developer causes the penetrant surface and seepage that is still present in any defect. These two properties allow defects to be easily detected at inspection time. The developer is then allowed to get the required dwell time before checking.

5. Check:

In the case of a fluorescent inspection, the inspector will use ultraviolet radiation of an intensity appropriate to the intent of the inspection operation. This must be done in a dark room to ensure a good contrast between the glow emitted by the penetrant in the defect area and the unilluminated surface of the material. Inspectors carefully inspect all problematic surfaces and record any problems. Problematic areas can be marked so that the indicated location can be easily identified without the use of ultraviolet lighting. The inspection should be performed at a given point in time after the developer has been applied. Too short a time and the defect may not be completely removed, too long and the imprinting may make correct interpretation difficult.

6. Final cleaning:

After a successful inspection of the product, it is returned for final cleaning before being shipped, transferred to another process or deemed defective and reworked or scrapped. Note that if a defective part is not considered cost-effective, it may not go through the final cleaning process.

The above describes 6 steps to teach you how to test with Sherwin fluorescent penetrants. In addition, Shenzhen Oudejie Technology specializes in the sale of new original German imported Sherwin Sherwin penetrant, and promises to sell products are new original imported, while providing our customers with quotation, selection, product information and other services。