Service Hotline

+1 4152729688

2023-09-21 16:24:12

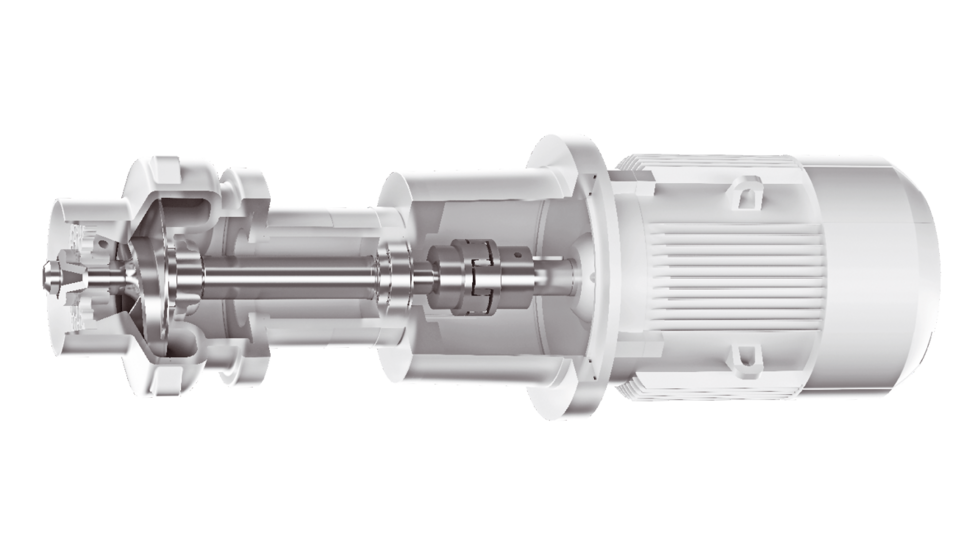

The efficient operation of the centrifugal pump depends on the constant high-speed rotation of its impeller. For high-viscosity feeds, centrifugal pumps become increasingly inefficient: resistance is greater and higher pressure is required to maintain a specific flow rate. Therefore, in general, centrifugal pumps are suitable for low-pressure, high-volume, pumping liquid applications with viscosity between 0.1 and 200 cP.

Slurries such as mud or high-viscosity oils can cause excessive wear and overheating, which can lead to damage and premature failure. Positive displacement pumps typically operate at fairly low speeds and are less prone to these problems.

Any pumping medium that is shear sensitive (separation of emulsion, slurry or biological liquid) may also be damaged by the high-speed operation of the centrifugal pump impeller. In this case, the lower speed of the positive displacement pump is preferred.

Another limitation is that, unlike a positive displacement pump, a centrifugal pump cannot provide suction when dry: it must first be pumped with the pumped fluid. Therefore, centrifugal pumps are not suitable for any application with intermittent supply. In addition, if the feed pressure is variable, the centrifugal pump produces a variable flow rate; Positive displacement pumps are not sensitive to pressure changes and will provide a constant output.

The above content introduces what are the limitations of KNOLL centrifugal pump, what are the advantages and disadvantages of KNOLL centrifugal pump. In addition, Shenzhen Oudejie Technology specializes in selling new original German imported KNOLL centrifugal pumps, and promises to sell products are new original imported, while providing our customers with quotation, selection, product information and other services.