Service Hotline

+1 4152729688

2023-09-21 16:22:50

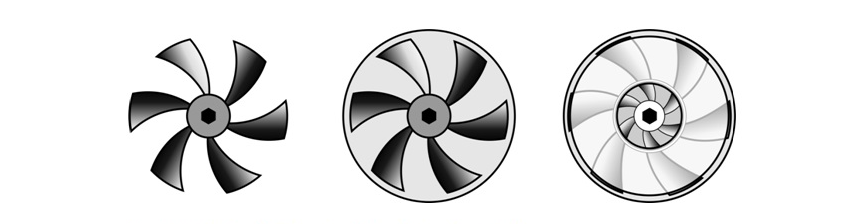

KNOLLCentrifugal pumpImpeller is the key component of centrifugal pump. It consists of a series of curved blades. These are usually sandwiched between two discs (closed impellers). For fluids containing solids, open or semi-open impellers (supported by a single disc) are preferred.

The fluid enters the impeller along its axis (the "eye") and flows out along the circumference between the blades. The impeller is located on the other side of the eye, is connected to the motor via the drive shaft and rotates at high speed (usually 500-5000rpm). The rotating motion of the impeller accelerates the flow of fluid through the impeller blades into the pump housing.

There are two basic pump housing designs: volute type and diffuser. Both designs are designed to convert fluid flow into controlled discharge under pressure.

In the volute, the impeller is offset, effectively creating a curved funnel whose cross-sectional area increases toward the pump outlet. This design causes fluid pressure to increase towards the outlet.

The same basic principles apply to diffuser design. In this case, the fluid pressure increases as the fluid is discharged between a fixed set of blades surrounding the impeller. Diffuser designs can be customized for specific applications, making them more efficient. The volute is more suitable for applications involving entrainment of solids or high viscosity fluids when it is beneficial to avoid additional contraction of the diffuser blade. The asymmetry of the volute design results in greater wear on the impeller and drive shaft.

The above content introduces what is the working principle of KNOLL centrifugal pump and how KNOLL centrifugal pump works. In addition, Shenzhen Oudejie Technology specializes in selling new original German imported KNOLL centrifugal pumps, and promises to sell products are new original imported, while providing our customers with quotation, selection, product information and other services.