Service Hotline

+1 4152729688

2023-09-21 15:41:25

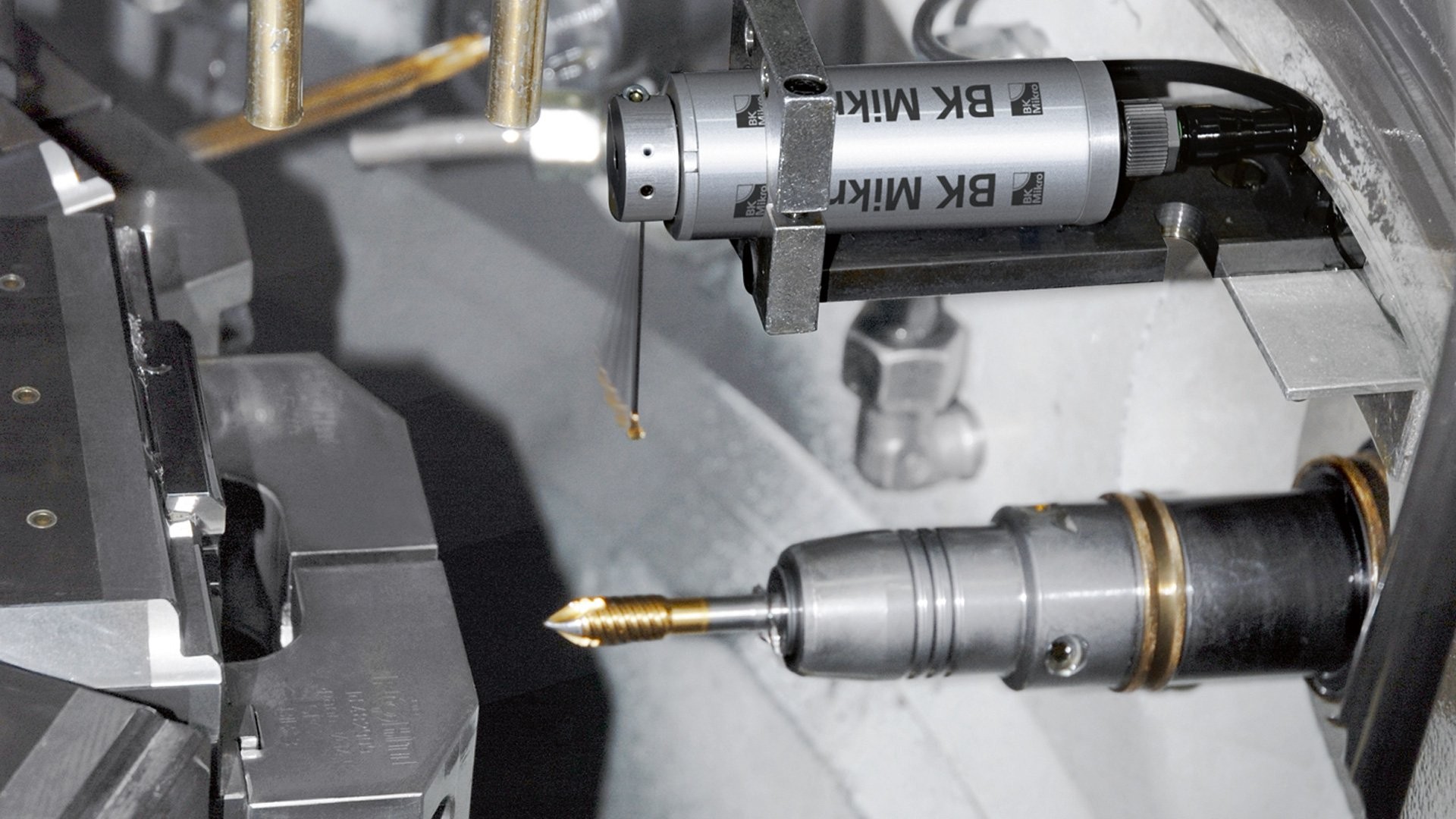

BK Mikro Tool inspection systemThe physical structure is made up of four basic components - the scanner, the control unit, the connection cable and the mounting bracket. These four basic components are integrated together to form a tool monitoring system.

1. Control unit:

The control unit is the brain of the system. The location where the control unit stores the position of the object from the scanner. The controller compares the position of subsequent checks to verify that the object is in the correct position. If the object or region is incorrect, the control unit sends a signal to the machine to control the stopping process, or if the machine is capable, redundant tools may be called. There are 2 main versions of the control unit in BK Mikro, Basic and Advanced.

1. Premium Edition offers 4 variants; Digital IO, Profibus, DeviceNet, and PROFINET

2. The basic version is a low-cost version, which only supports one function or left-right inspection.

3. Premium Edition is designed to monitor more than 512 objects or functions.

4.Profibus, DeviceNet, and PROFINET versions use these fieldbus protocols to communicate with the CNC and allow for an unlimited number of tool locations.

2. Scanner:

The scanner is the main component of the tool monitoring system. The scanner can be probe type or rod type and is fixed in the mounting bracket. The scanner can perform one-way or bidirectional scanning. This helps check for tool defects, skews, misalignments, etc. The scanner can check for differences as small as 0.002 inches, depending on the length of the scanning rod.

Third, connecting cable:

The connection cable runs from the control unit to the scanner motor. Depending on the requirements of the application, the length of the cable varies from 0.5m to 15 m. They also have right Angle or right Angle connections.

Fourth, installation bracket:

The system comes with a split-type fixture holder to hold the scanner in place. Typically, one of the customer installation technicians will fabricate a custom stand to place the scanner in the correct position in the machine for inspection.

The above content is the most important four components of BK Mikro tool testing system, in addition, Shenzhen Oudejie Technology professional sales of original imported BK Mikro tool testing system, and committed to sales of products are new original imports, while providing our customers with quotation, selection, product information and other services.