Service Hotline

+1 4152729688

2023-09-21 11:54:31

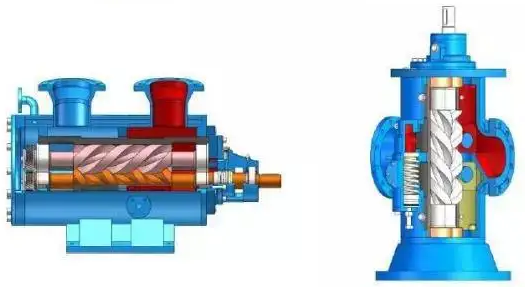

Screw pumpThere are many uses in a variety of different industries, including manufacturing, mining, and oil and gas. Most of these applications deal with high-viscosity fluids, such as oil or bitumen, or polyphase fluids, which means a mixture of liquid and vapor in the fluid flow. Here are some examples of using screw pumps:

Hydraulic and lubrication systems - Many lubrication and hydraulic systems use screw pumps. These are usually small three-screw pumps. Lubrication and hydraulic systems like these are used to supply lubricants to large machinery, to provide hydraulic power to high-pressure hydraulic systems or to operate elevators in buildings.

Heavy oil pipeline - When pumping high viscosity crude oil, screw pumps can provide the ideal solution for transporting crude oil through pipelines. Capable of pumping higher viscosity than centrifugal pumps and capable of pumping higher flow rates than reciprocating pumps, screw pumps are commonly used in these applications. In these cases, very large pumps are sometimes used to achieve the desired flow rate. These pumps are usually driven by large electric motors or diesel engines.

Multiphase pumping - Multiphase pumping refers to pumping a mixture of fluid and steam together and is considered one of the most challenging pumping applications. When the liquid enters, the compressor can be severely damaged, just as most pumps are severely damaged when air enters. If constructed correctly, a screw pump can be a hybrid of a pump and a screw compressor, capable of handling liquids and gases.

In order to prevent damage to the screw pump when the air enters, the screws must not contact each other. For this purpose, a four-screw pump is usually used. In addition to this, the pump must also be equipped with a liquid guide, which is sometimes built into the pump, but can also be easily added from the outside. The liquid shoe is a pressure vessel used to collect the fluid discharged from the pump. As the air mass passes through the supply pipe, a small pump removes the liquid from the boot and injects it into the pump. This provides light lubrication to the screws and lining and seals the gap between the parts so the air/gas being pumped does not slide backwards into the low pressure area in the pump. Depending on the capacity of the liquid guide vessel, the multiphase pump can pump 100% steam for a few minutes.

Shenzhen Oudejie technology specializes in the sale of German original imported knoll Kono screw pump, and committed to the sale of knoll Kono screw pump products are new original imported, while providing our customers with quotation, selection, product information and other services.