What is a centrifugal pump?

Centrifugal pump is an automatic system composed of two main parts; Pumps and motors. The key component of the centrifugal pump core is the impeller, which rotates rapidly around the axis during operation, applying centrifugal force to the fluid so that it can pass through the pump housing and reach the suction inlet. The impeller is made of highly corrosion-resistant cast iron with curved blades and guard plates. Usually, unless the pump system already has self-priming capability, the centrifugal impeller always needs to be fully submerged in water to start during operation.

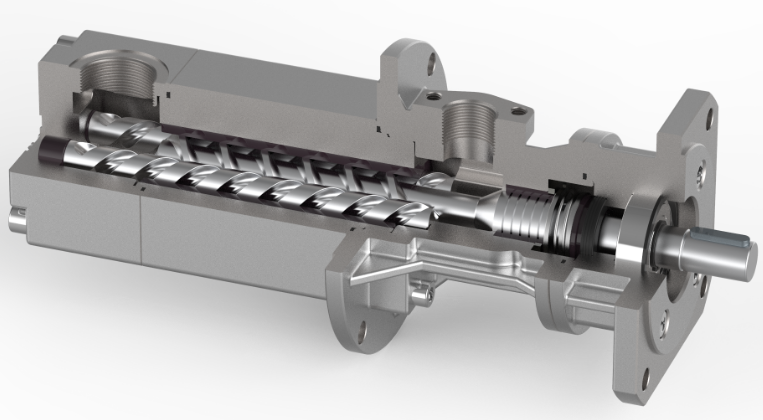

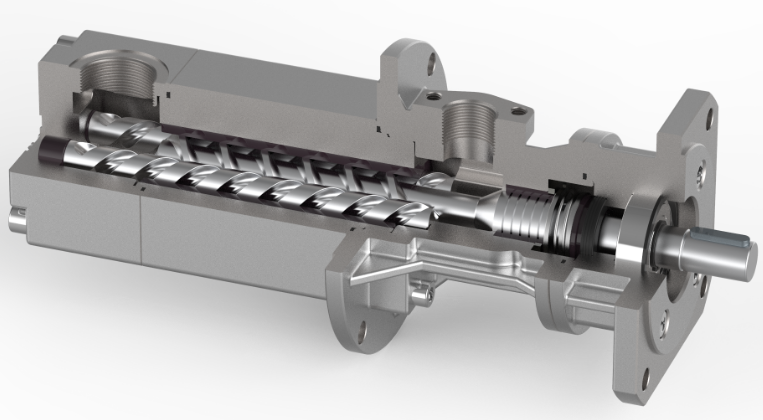

Because a centrifugal pump uses a rotating impeller system and operates at a low/medium pressure head, it operates differently from many other pumps that typically fall into the positive displacement pump category. These pump types typically use diaphragm pump systems or reciprocating designs to transport fluids.

Centrifugal pumps are a highly versatile pump system that is widely used in domestic and commercial applications across many industries because they are able to move more fluids than any other pump type on the market. They also come in many different shapes, colors, sizes, and materials, including sanitary, industrial, and ATEX implementations.

How does the centrifugal pump work?

The basic working principle of any centrifugal pump is that the fluid enters the pump inlet, flows to the impeller shaft and rotates exponentially along the impeller blade inside the pump housing, and then discharges the fluid to the discharge side. This is then repeated to direct more fluid through the pump inlet for precise, controlled and repeatable operation.

Different centrifugal impeller types

There are usually three different impeller types available for different applications, namely open, semi-open, and closed impeller pump types.

Open impellers are often chosen for abrasive applications or applications with suspended solids so that fluids can be moved easily through the blade shaft. However, they are slightly less efficient because the fluid mixes almost immediately with the liquid that has already flowed through the pump housing.

Semi-open impeller types use a shield wall to increase the robustness of the blade while still having one side open. Similar to the open impeller type, semi-open impellers can be used for fluids that contain partial solids.

Enclosed impeller types have protective walls around the rear and front of the impeller blades, which makes the impeller types very strong. These are commonly used in large industrial pumps and low viscosity applications where there is no solid in the suspension due to the increased likelihood of fluid clogging during operation.

Centrifugal casing type

There are two main options for centrifugal pump housings around the impeller, including diffusers and volute designs.

In volute centrifugal pumps, the flow rate increases steadily and the curved design creates a chamber for the fluid to direct it towards the drain pipe.

The diffuser housing has a guide blade on the outside of the impeller to increase the pressure and diffuse the liquid for a more controlled operation.

Main features of centrifugal pump

Centrifugal pumps are widely used. They are available in many different shapes and sizes to meet a variety of installations and requirements, whether you need your pump to be electrically or magnetically driven, self-priming, capable of handling sanitary liquids or large enough for large industrial applications, there are centrifugal pump solutions available.

Centrifugal pumps are ideal for high flow applications and operate more efficiently than pneumatic pumps.

Another key feature of centrifugal pumps is that they can be easily modified to meet the different requirements of the end user. For example, accessories such as heating sleeves, self-priming chambers and sanitary shields can be used to achieve the perfect pump solution.

The above content is introducedKNOLLKono centrifugal pumpHow it works and its advantages! The problem. In addition, Shenzhen Oudejie Technology specializes in selling new imported KNOLL centrifugal pumps, and promises to sell products are new imported products, while providing our customers with quotation, selection, product information and other services.