Service Hotline

+1 4152729688

2023-09-22 11:25:08

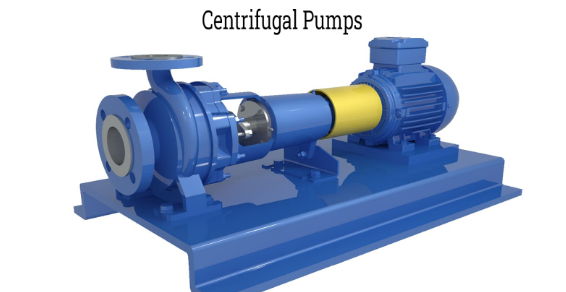

What is a centrifugal pump?

KNOLL Kono centrifugal pumpHydraulic machinery is defined as the use of centrifugal forces acting on a fluid to convert mechanical energy into hydraulic energy. This is a machine that uses rotation to apply velocity to a liquid and then converts that velocity into flow. Each centrifugal pump consists of mechanical parts that make the operation of the pump possible.

This mechanical component includes a pump shaft mounted on the bearing, a sealing mechanism to prevent uncontrolled leakage of the pump, structural components designed to handle the load and stress imposed on the pump during use, and to allow the pump to be returned and restored to its original specifications.

Components of centrifugal pump

• Axis

• Impeller

• Casing

• Straw

• Delivery pipe

Centrifugal pump shaft

It is the central part of the pump and rotates with the impeller when connected. The shaft is connected to the prime mover for power. The shaft fits perfectly with the ball bearing.

Centrifugal pump impeller

It consists of a set of blades bent backwards. It is mounted on the shaft of the motor. This is called the rotating part of the centrifugal pump enclosed in a waterproof housing. The impeller spins and imparts velocity to the liquid.

Centrifugal pump casing

This is the channel around the impeller and will be airtight. It is manufactured in such a way that the kinetic energy of the water discharged at the outlet is converted into pressure energy before the water leaves the casing and is transported to the delivery pipe. It plays a protective role and thus protects the system. The housing converts the velocity generated by the impeller into a steady flow. The casing of the centrifugal pump is basically divided into three types: volute, vortex casing and casing with guide vane.

Volute or spiral casing

The impeller surrounds this type of housing. This casing provides a continuous increase in the flow area, thus reducing the speed of the water and increasing the pressure.

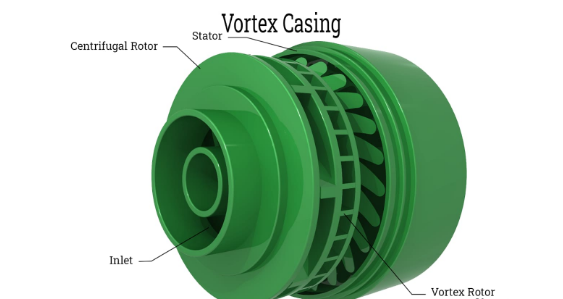

Vortex casing

The housing is a circular chamber located between the housing and the impeller. The fluid from the impeller must first pass through the vortex chamber and then through the volute. The velocity energy has been converted into pressure with good efficiency compared to the volute.

Housing with guide blade

In this type of housing, there are blades around the impeller. These blades are arranged and designed in such a way that the water from the impeller passes through the guide blades without impact and forms a channel of increased area through which the water passes and reaches the conveyor belt pressure to leave.

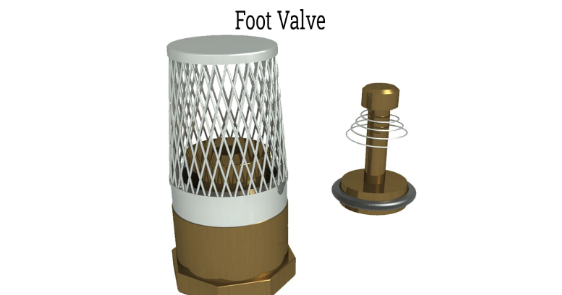

Suction tube with filter and bottom valve

The suction tube has two ends. The first end is connected to the inlet of the pump, and one end is immersed in the water in the pool. At the lower end of the suction tube, a bottom valve is installed. The valve only opens upward, as it will be a one-way type. To prevent unknown and unwanted objects from entering the suction pipe, a filter is installed at the end of the pipe.

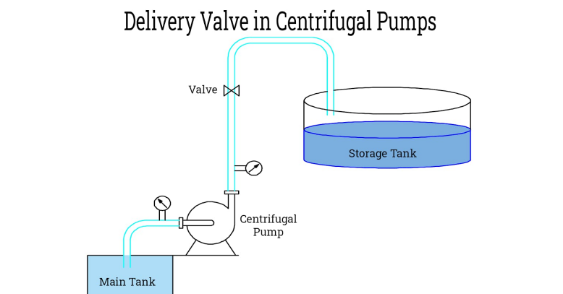

Delivery valve

The delivery valve also has two ends. One end is connected to the outlet of the pump and the other end delivers the water to the desired height.

The above content introduces what is the working principle of the KNOLL Kono centrifugal pump and what components the centrifugal pump is composed of. In addition, Shenzhen Oudejie Technology specializes in selling new imported KNOLL centrifugal pumps, and promises to sell products are new imported products, while providing our customers with quotation, selection, product information and other services.